FENN Solutions

Repeat Customer Purchases new fully automated NF Swager

Download the study here: Case Study NF Automated Swager

Objectives & Background:

- A repeat customer approached FENN looking for a solution to increase their production of hypodermic needles for medical applications with the purchase of a new machine.

- The customer was working with a manual feed swager, but realized their production volume, part consistency, and part quality were not meeting their expectations and specifications.

- To meet production quotas, the customer decided to purchase a fully automated feed unit.

- The customer required a swager with capabilities to run 23-27 (.025”-.016”) gauge hypodermic needles.

FENN’s Solution:

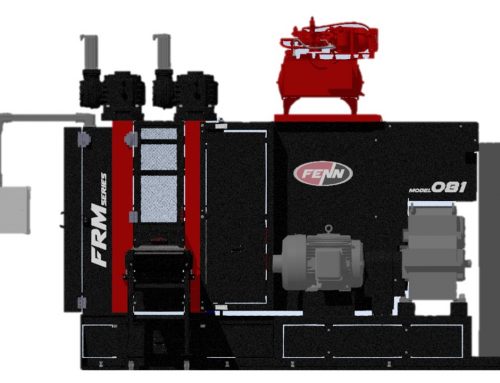

- FENN’s experts engineered a new design to make a fully automated solution.

- With the customer’s production requirements in mind, FENN designed a machine capable of producing higher amounts of hypodermic needles with more accuracy.

- For maximum productivity and minimum changeover time, FENN designed this feeder with automatic feeding capabilities, collection bins, and an easy die changeover process.

- The latest FENN software was implemented into a new B&R touch screen display for a user-friendly operator interface.

Value to Customer:

- The customer received a new NF Automated Swager.

- The machine increased the customer’s productivity, minimized operator involvement, and reduced downstream costs.

- New production volume of up to 300 pcs/hour

- The B&R software and touchscreen control system are state-of-the-art technology but still utilize easy to maneuver screens – making training easy for operators.

- The NF Automated Swager comes complete with FENN’s guarantee; a one-year warranty, training, and the ability to purchase spare parts if needed.