Medical Device Industry

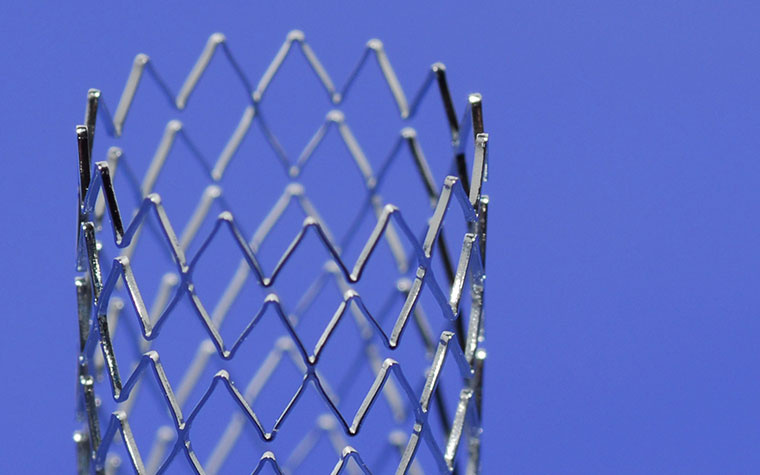

Our innovative metal forming equipment is instrumental to the medical device industry. For over 100 years, we have been providing our customized machinery to companies producing medical devices used in almost every specialty, including (but not limited to): orthodontic wires, replacement joints, catheters, stents, cosmetic applicators, cardiovascular devices, and endoscopy scopes.

We know the importance of quality in any manufacturing, but especially when it comes to medical devices. Our commitment to precision and perfection paired with our ability to create a customized piece of machinery to meet our clients’ exact specifications makes us an ideal partner for the medical device industry.

Our turks heads, swagers, wire flattening and shaping lines, and spring coilers are being used worldwide to help medical device producers increase their efficiency and profitability without ever sacrificing quality.

To find out more about how our turks heads, swaging equipment, wire flattening and shaping lines, or spring coilers can improve the efficiency and quality of your medical device production, contact FENN now.

Our innovative metal forming equipment is instrumental to the medical device industry. For over 100 years, we have been providing our customized machinery to companies producing medical devices used in almost every specialty, including (but not limited to): orthodontic wires, replacement joints, catheters, stents, cosmetic applicators, cardiovascular devices, and endoscopy scopes.

We know the importance of quality in any manufacturing, but especially when it comes to medical devices. Our commitment to precision and perfection paired with our ability to create a customized piece of machinery to meet our clients’ exact specifications makes us an ideal partner for the medical device industry.

Our turks heads, swagers, wire flattening and shaping lines, and spring coilers are being used worldwide to help medical device producers increase their efficiency and profitability without ever sacrificing quality.

To find out more about how our turks heads, swaging equipment, wire flattening and shaping lines, or spring coilers can improve the efficiency and quality of your medical device production, contact FENN now.

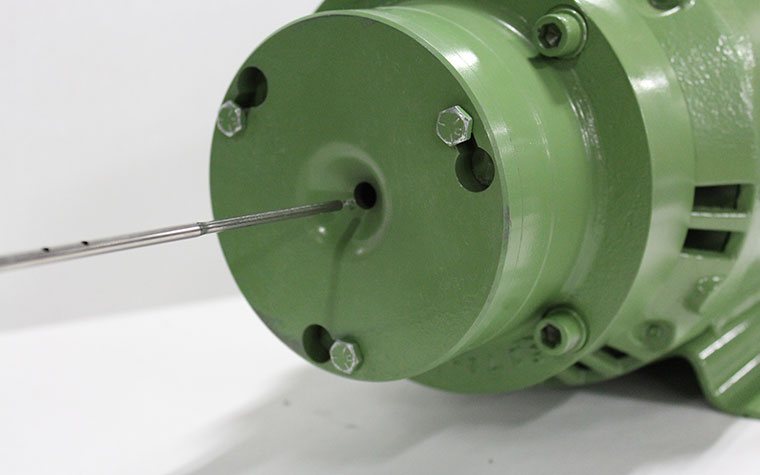

Our swaging machines service many facets of the medical industry. Swagers are a popular method to shape or resize tubes, rods, and wires because the chip-less forming processes produces no waste – so precious materials are not scrapped. Not only are FENN swaging machines cost effective, the end product they produce offers an impeccable grain structure and strength, which is vital in the medical device industry. Integrating automation into the swaging process provides the capacity for exact replication with each production run. In the medical industry precision is crucial to quality production. Using automation during the swaging process can ensure face-paced production of both quality and quantity. NF and 1F sized FENN swagers are commonly used to produce fine points on a variety of medical related devices such as needles and surgical needles with no radius. Small OD material is possible on FENN NF swaging machines.

Swagers can be used for multiple applications, simply by switching the dies a new application can be performed. On FENN NF and 1F sized swagers, the changeover time is very fast which allows for maximum productivity and uptime. FENN designs and manufactures dies in-house – contact us for spares.

Our swaging machines have been used to make:

- Marker bands for catheters

- Hypodermic needles

- Medical & surgical tools

- Surgical needles

- Optical instruments

- Dental water picks

- Dental implants

- Cable and wiring for electrodes

FENN’s swaging equipment is fully integrated by the OEM. We are a single source supplier, eliminating the need for multiple vendors for the production of one system. Integrated automation improves equipment safety and product quality. Save time with collaborative robotics and allow FENN to design, coordinate, test & validate your system for you.

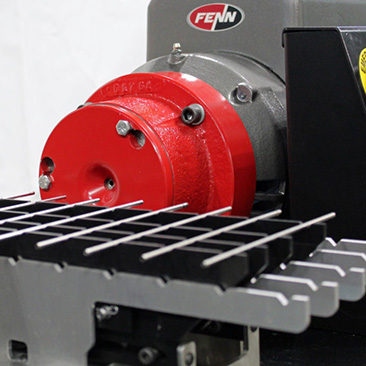

Flat wire has many uses in the medical industry. FENN wire flattening and shaping lines use extreme precision to make high-quality wires out of both ferrous and non-ferrous materials. In the medical device industry, reliability and quality are of the utmost importance, which is exactly what our wire flattening and shaping lines have to offer – and with a full line of optional accessories, there is no requirement too demanding. Custom lines can be designed, contact us today.

Flat wire has many uses in the medical industry. FENN wire flattening and shaping lines use extreme precision to make high-quality wires out of both ferrous and non-ferrous materials. In the medical device industry, reliability and quality are of the utmost importance, which is exactly what our wire flattening and shaping lines have to offer – and with a full line of optional accessories, there is no requirement too demanding. Custom lines can be designed, contact us today.

Alloys commonly used are nitinol, titanium and stainless steel.

Examples of medical-related products, made using FENN equipment includes:

- Catheter wire, curled and cut to make marker bands

- Copper insulation used for electrical equipment

- Scalpel blades produced on variety of FENN shaping equipment

- Orthodontic/dental arches (WFS used in conjunction with coilers)

- Research and development

FENN wire shaping lines are not limited to the rolling of natural edged flat wire: square, rectangle, trapezoid, oval, half round, and many other shaped wire can be rolled with the proper selection of equipment. With more than 100 years of experience in the engineering and manufacturing of metal forming machinery, we provide state-of-the-art equipment to suit your most demanding medical-related production needs.

Each application is reviewed in detail by our experienced engineering staff to determine the correct arrangement of equipment needed to satisfy your requirements. Many applications can be achieved with a single stand, two-stand tandem or three-stand tandem mill arrangement. For applications with more aggressive reductions, additional stands may be added or used in conjunction with Edgers, Turks Heads, Draw Blocks, or other metal forming equipment pertinent to the process and material requirements.

Torin spring coilers are used for various applications throughout the medical industry. Torin spring coilers have the earned reputation of being reliable, repeatable machines that produce precise and accurate springs. Precision is crucial in the medical industry.

The Torin FZ-100 sized spring coiler can produce springs with stainless steel with a wire diameter of .003” to .015” (.076mm to .38mm).

The Torin FZ-10 sized spring coiler can produce springs with stainless steel with a wire diameter of .008” to .028” (.20mm to .70mm).Some common examples of medical applications include:

- Catheter guide wires

- Hypodermic retractable springs for use in “single Use” needles

- Dental arches

- Medical tools

Torin spring coilers can be integrated with additional equipment to provide a secondary process to ensure clean and sanitized products.

Our trusted Torin spring coilers offer an efficient, customizable method for producing quality springs. The highly adaptable FZ series was designed for fast set-up and changeover of springs using the powerful 19-inch touch screen interface. The Torin FZ series spring coiler can quickly produce a wide variety of springs and wire forms on a single wire coiling machine, all with uncompromised accuracy, repeatability and flexibility. Learn more about our FZ series here

FENN drawbenches and draw blocks are used for drawing various medical tubing.

A majority of medical drawbenches are hydraulic, because this configuration lends itself well to shorter drawing applications.Titanium, nitinol, and stainless steel tubing can be used on FENN drawbenches to produce:

- Hypodermic tubing

- Medical tubing

Within the medical industry, FENN drawbenches can be used to draw out tubing, reducing it for the next step on the production process. Some of these next steps can include:

- Cutting

- Internal isolation

- Internal wiring

FENN’s drawbenches can be designed with different levels of automation including but not limited to:

- Part loading

- Part unloading

- Inline cutting equipment – which creates additional efficiency within the process

Draw Blocks: FENN draw blocks are used with continuous coil of wire or tube – much larger lengths than what is drawn on a drawbench – the block can draw tube or wire down to a certain size then the material can come off the block and go to another process such as:

- Annealing

- Cutting

- Machines for twist and cut

- Machines for applying coating onto the product