Metal Drawing Machinery

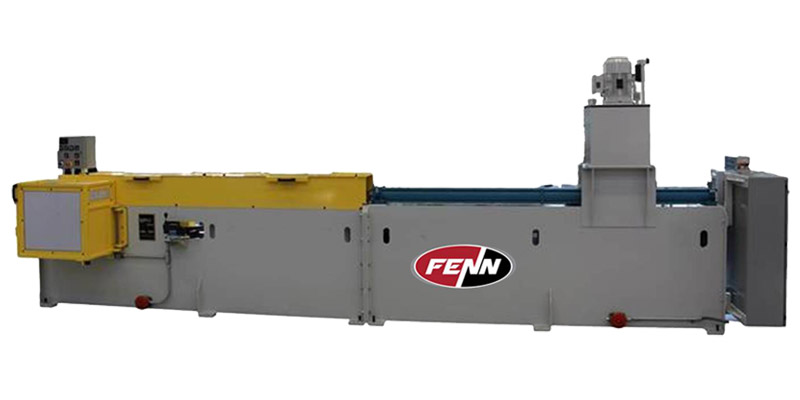

Systems up to 230 ft. long (70.1m) with 200,00 lbs. pull (90,718.474 kg.)

Designed & Built to Maximize Productivity

FENN has been a leader in producing high-quality drawing machinery for over 120 years. With the entire design, build and test process under one roof, our team provides a seamless, peace of mind experience.

Our experts take the time to design and build the right metal drawing machine to fit your exact specifications and fulfill your unique production requirements. FENN’s experience building standard metal forming equipment, as well as customized metal forming machinery solutions, provide product and service offerings that increase precision and productivity.

Custom Design

Capabilities

We provide equipment designed with quality, production, and safety in mind. Suitable for any application, large or small, we offer drawbench machines ranging from 2 feet (60.96 cm) long and 250 lbs. (1.1 kn) of pull force to 230 feet (70.1 meters) long and 200,000 lbs. (890 kn) of pull force.

Chain Type

Drawbench

Hydraulic

Gripper

Fully Automated Chain

Type Drawbench

Hydraulic

Drawbench

Manual

Gripper

Manual Chain Type

Drawbench

FENN creates rugged, innovative, state-of-the-art metal forming machines that are customer engineered and expertly manufactured. Contact us today to learn more about FENN’s ability to custom design a drawbench to suit your unique applications and production requirements.

Customized and Flexible Designs

Our drawbenches are available in both hydraulic cylinder and motorized chain type units. Each drawbench can be customized with a full selection of ancillary options to suit a variety of applications.

Optional features including, but not limited to:

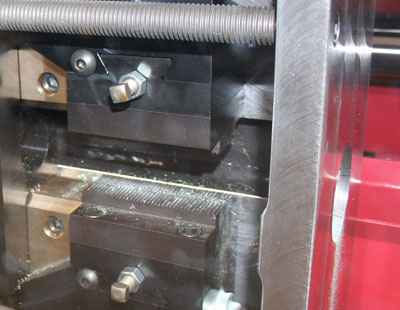

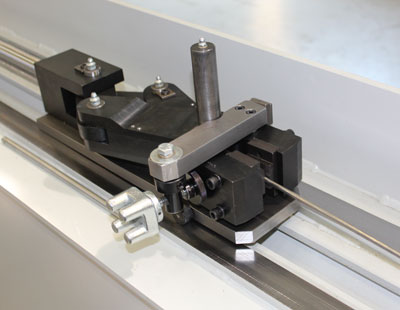

- Manual or hydraulically actuated grippers with removeable tooling for wear replacement and tooling change for various wire, rod, and tube sizes

- Single or multi-draw benches available

- Fully articulating die boxes available

- Dry and wet lube systems

- Turks head mounting provisions

- Draw pull force measurement and readout

- Full draw-cycle automation

- Roll or swager type pointers

- Material handling systems – manual or automated

- Safety covers for guarding and electrical interlocks

Custom Designs for Every Industry and Application

FENN designs and manufactures a full line of drawbenches used for straight length die-drawing of round rod, wire or tube and draw block equipment for continuous coil drawing. FENN drawing systems can be designed up to 230 ft. long (70.1 m) with 200,000 lb. pull (90,718.474 kg.). A wire or tube drawing machine can be integrated to work with other FENN equipment, such as a FENN Turks Head, for producing straight lengths of shaped rod or wire or FENN Swagers for pointing material.

| Typical Materials | Applications | Industries | Drawbench Types |

|---|---|---|---|

| Steel | Tubes | Research | Chain |

| Copper | Solid Rolls | Medical | Hydraulic |

| Aluminum | Shape Wire | Production | Ball Screw |

| Superconducting | Nuclear | Semi-Automated | |

| Exotic Metals | Superconducting | Fully-Automated | |

| Precious Metals | Pneumatic |

Spares from the OEM!

FENN understands that uptime is key to your business’ productivity and profitability. We offer a full range of spare parts available for both FENN and Torin metal forming machines. With an extensive inventory, FENN can offer a wide array of parts shipped quickly to your door. Our knowledgeable staff will help to ensure you receive the necessary parts to keep your equipment running effectively with minimal downtime. Using FENN spare parts is an essential aspect to maximizing your machine’s efficiency. Don’t know exactly what you need? Our experienced staff will take the time to work with you to understand your unique requirements.

Upgrade Program for Your Aging Machinery

Because FENN machinery upholds a legacy of being quality, reliable and long-lasting, FENN has developed an upgrade program for upgrading, rebuilding or retrofitting your existing FENN equipment. Customers can maximize their machine productivity for aging equipment and extend the machine’s usable life.

We’re Here For You – Training, Support & Service

As a century old company, we are proud of the equipment we design and build, always ensuring it meets your production requirements. We offer comprehensive training programs that can be tailored to meet your business’ needs. Whether you have purchased a new metal forming machine, upgraded existing equipment or your experienced staff is retiring, FENN is available to answer questions and offer training to keep your business productive. Let us know how we can help!