TS Precision’s Proforma Stamping Machinery:

- The Proforma series is capable of producing highly finished, complex parts

- Efficient process enables minimal material consumption

- Reduce downtime of tooling adjustment & material changeover

- Increase production speed & efficiency when completing complex parts on a single machine

- Ideal for making complex parts in automotive, electronics, building hardware, & general merchandise

Learn More about how each of the Proforma models can assist you with your project requirements by reading below, contact us, or download the brochure.

Product Overview

SF SERIES

The Smart Forming SF Series is a highly efficient CNC machine – an impressive 40% more efficient as compared to the conventional CNC model. Download the brochure for machine specifications.

- CNC machine with competitive cost performance

- Designing and fabrication of cam is unnecessary

- Material-waste decreased comparing with press machine bends that add value to finished products

- Common use dies allow excellent cost-performance (some dies cannot be used as common)

- All unit conditions are displayed on a digital screen. Numerical control is possible.

- Both strip material and wire material can be processed with the same machine

- Complex bending processes are possible for many different applications

- Can be equipped with a tapping and welding unit to streamline

OPERATIONAL PANEL

The touch-screen control panel is included as standard. Various information is displayed with easy operation

STAMPING UNIT

The motion control is adopted. Changing speed and movement is possible.

BENDING SLIDE

Timing and stroke change are made by program exchange in substitution for cam change over. Tooling change over time can be shortened remarkably.

ENERGY SAVING

40% more efficient compared to a conventional CNC Machine (IF Series)

FEED UNIT

Reliable CNC gripper feed unit is adopted. Stroke-change, multi-stage feeding and reverse feeding are possible by changing programs.

FORMING UNIT

Forming area is 1.5 times larger than RF and IF series. This allows you to produce longer parts. By using an adapter ring and special slider, some of the tooling of R/ RF/ and the IF series can be used.

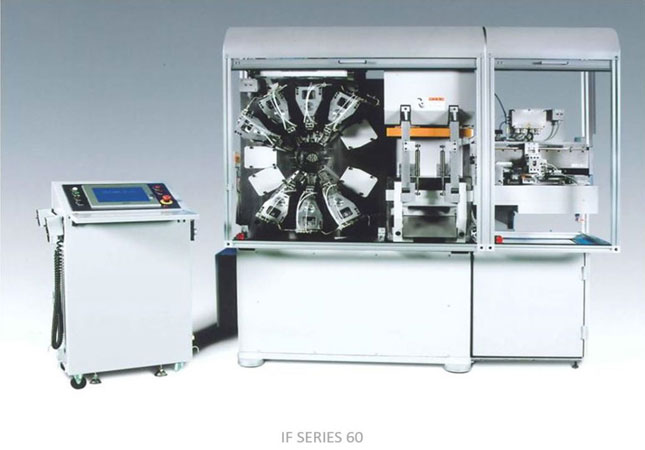

IF SERIES

The Intelligent Forming Series (IF) has improved tooling changeability & repeat-ability with CNC technology.

Download the brochure for machine specifications.

- Both strip material and wire material can be processed with the same machine

- Waste is decreased due to reduced material consumption

- Circumferential bending position produces exquisite finished bends that add value to the product

- Complex bending processes are possible for many different applications

- Can be equipped tapping and welding unit streamline

- Numerical control allows for quick product development and short tooling change over time

- Common-use dies for excellent cost performance

RF SERIES

Update: As of December 2020, the PROFORMA RF Series (RF-20 / RF-60 / RF-80) have been discontinued. TSP will provide the SF Series of CNC machines as the successor of the RF Series. The SF Series has been designed with the same system as the RF Series, with rotary cam to use pusher and returning cam. If the customer requests a special RF Series machine, TSP will provide it as a custom option.

TSP will continue to provide spare parts for existing RF-Series machinery.