Which Spring Coiler do you Need?

Deciding Between Single Point and Dual Point Coilers: Across a variety of metal forming industries, spring makers rely on quality coiling equipment to create high-quality springs for their customers. Around the world, people have been making springs for decades with the primary difference being the manufacturing methodology.

On a basic level, there are two widely recognized methods of making compression springs with CNC machinery, each way utilizing a different type of machine. These metal forming machines are called single point coilers and dual point coilers. Some of the main differences between these types of metal forming machines are that each requires a different type of tooling and dual points have two outside points of contact with the wire it coils, while single points only have one outside point of contact and an arbor inside. Since the introduction of the first automatic spring coiler, there has been an unending debate as to which method of spring coiling produces a higher quality, more durable, spring. While there are some key differences in the way the springs are made, studies have shown that, from the point of stresses for metal forming and residual stresses post metal forming, there is no difference between dual point and single point coiling. Meaning, the quality of spring is equal – but individual capabilities of each metal forming machine limit the variety of springs that can be produced.

Single Point

Double Point

So why are there two different kinds of spring coiler machines? Historically speaking, spring makers in Europe initially developed and used the dual point method while spring makers in North America have used the single point coiling method. Both types of coiling methods have strengths and weakness – and both types can make good springs when properly set up. Today, both types of spring making equipment are available across the world and usage largely relies on the preference of the operator and set up staff that use the machine. Read on to understand how each type of machines works to develop springs and the benefits and drawbacks of each technology. Contact us today to learn which machine is right for your business!

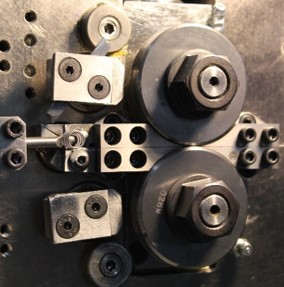

Torin Dual Point Spring Coilers: Dual point spring coilers are classified as such because they have two outside coiling points of contact with the wire as it makes the spring. Because of their design, they require the use of an arbor only for cutoff. A dual point coiler can manufacture round compression and extension springs. If a shop’s only requirement is to produce compression springs, the dual point coiler helps to eliminate the risks associated with marking the ID of the coil. FENN is proud to offer a full line of Torin brand dual point spring coilers. One advantage to FENN’s line of Torin dual point coilers is that users save on set-up time with multiple programmable axes for diameter, which makes for quick changeovers from a left to a right-hand spring helix. With Torin dual point spring coilers, there are also time savings with movable wire line as feed rolls and guides do not need to be changed with wire size adjustments. Additional features of a Torin dual point spring coiler include programmable horizontal and vertical pitch, programmable servo elliptical cutter motion, and complete system diagnostics available through the user interface.

Torin Dual Point Spring Coilers: Dual point spring coilers are classified as such because they have two outside coiling points of contact with the wire as it makes the spring. Because of their design, they require the use of an arbor only for cutoff. A dual point coiler can manufacture round compression and extension springs. If a shop’s only requirement is to produce compression springs, the dual point coiler helps to eliminate the risks associated with marking the ID of the coil. FENN is proud to offer a full line of Torin brand dual point spring coilers. One advantage to FENN’s line of Torin dual point coilers is that users save on set-up time with multiple programmable axes for diameter, which makes for quick changeovers from a left to a right-hand spring helix. With Torin dual point spring coilers, there are also time savings with movable wire line as feed rolls and guides do not need to be changed with wire size adjustments. Additional features of a Torin dual point spring coiler include programmable horizontal and vertical pitch, programmable servo elliptical cutter motion, and complete system diagnostics available through the user interface.

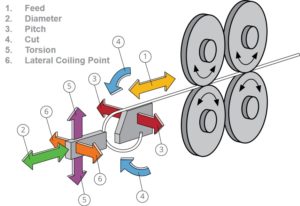

Torin Single Point Spring Coilers: Single point spring coilers only have one outside coiling point of contact. Unlike a dual point spring coiler, single point coilers require the use of an arbor for coiling and cut-off. The single point method of coiling allows for more tension control during the coiling process. When producing torsion springs, the “coiling point” can be raised or lowered during the coiling process, which allows for straight sections of the spring. Because of this feature, the single point coiler is much more versatile in the types of springs it can produce. FENN offers a complete line of Torin single point spring coilers that serve a variety of industries across a wide range of applications. Types of springs possible on a Torin single point coiler include extension, torsion, compression, constant force, magazine, shaped wire, wire forms, belting springs, rings, and many more! Due to their adaptability, companies looking to manufacture a variety of springs types may look to utilize a single point coiler for their business.

Torin Single Point Spring Coilers: Single point spring coilers only have one outside coiling point of contact. Unlike a dual point spring coiler, single point coilers require the use of an arbor for coiling and cut-off. The single point method of coiling allows for more tension control during the coiling process. When producing torsion springs, the “coiling point” can be raised or lowered during the coiling process, which allows for straight sections of the spring. Because of this feature, the single point coiler is much more versatile in the types of springs it can produce. FENN offers a complete line of Torin single point spring coilers that serve a variety of industries across a wide range of applications. Types of springs possible on a Torin single point coiler include extension, torsion, compression, constant force, magazine, shaped wire, wire forms, belting springs, rings, and many more! Due to their adaptability, companies looking to manufacture a variety of springs types may look to utilize a single point coiler for their business.

Catering to Both: Catering to both niches, FENN offers Torin single point spring coilers and Torin dual point spring coilers. FENN believes the best metal forming machine for any given customer is the machine that is best suited to the needs of their shop. Either type of machine can make quality springs, so it comes down to understanding each customer’s individual needs. If the customer’s production requires a mixture of springs types, and they want to change quickly from coil springs to torsion springs with bent ends, a single point coiler would prove more efficient. Depending on the shop and application it could be beneficial, from a productivity standpoint, to utilize both methods of coiling. For example, a shop may choose to use both dual point and single point spring coilers if their business’ production requires compression springs and torsion springs. For whatever your business requires, Torin spring coilers will get the job done.