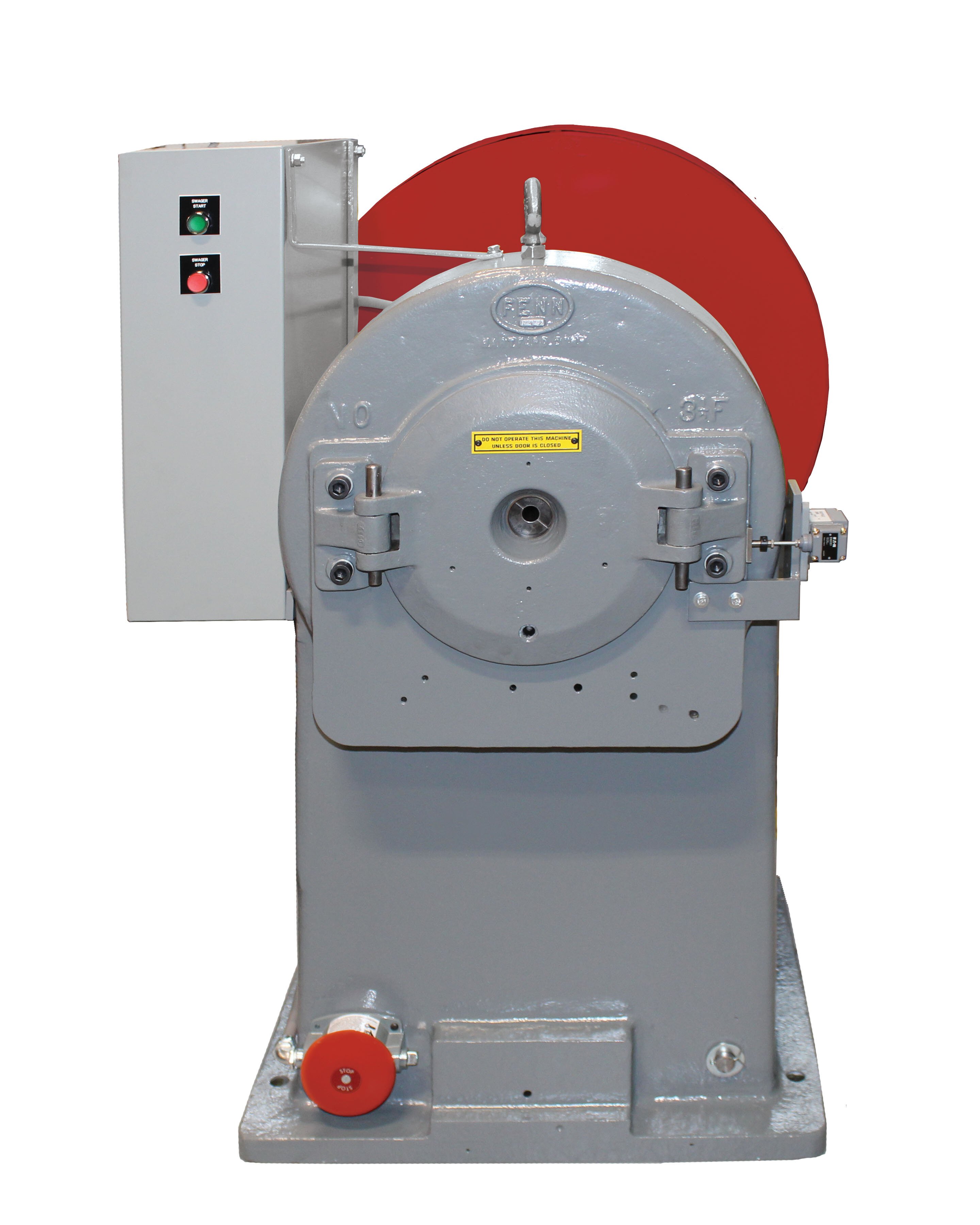

Custom Engineered Solutions

Our metal forming machines are design-to-build, with the entire process being conducted under one roof.

Metal Forming Machinery Expertise

From engineering the machinery to building and testing the final product, our diverse and skilled team works with you every step of the way to ensure the finished solution is exactly what you need.

1900

Founded in

124 +

Years Of Experience

32,000 +

Machines Built

Metal Forming Machines

Drawing Machines designed and built to maximize productivity. Systems up to 23 feet long (70.1m) with 200,00 pounds pull (90,718.474kg) >

Designed and built to ensure proper operation with spring coilers or other machinery,

including integrated safety features between machines >

Serving a Variety of Industries

Syringes, orthodontic wires, replacement joints, catheters, stents, cosmetic applicators, cardiovascular devices, and endoscopy scopes >

Service | Support | Training

After-Sale Services

Prompt customer service and support after the sale of every machine. FENN’s experienced technicians are on call to ensure minimal downtime and the highest levels of productivity for your equipment.

Training

FENN offers comprehensive training programs that can be tailored to meet your business needs. Whether you have purchased a new metal forming machine, upgraded an existing metal forming machine, or your experienced staff is retiring,

PM Plans

Don’t risk downtime! FENN offers Preventative Maintenance Programs to keep your machines running a the highest level of productivity,

Don't Just Take Our Word for It

Hear from people in your industry

Bilfinger Water Technologies

Prakash Shah, Engineer

High-quality machines and excellent service. We use FENN as our wire flattening and shaping line supplier for our wedge wire (screen wire) production because of their expertise in producing similar equipment and top-notch industry reputation. more >

Henry Royce Institute

Dr. Ross Nolan, Experimental Officer

FENN's advice and help were invaluable. FENN worked with the Institute staff to ensure that modifications were made to the initial design to meet stringent health and safety rules while also delivering a high-quality product to be used in the new Royce Hub Building in Manchester. more >

Ulbrich Stainless Steels & Specialty Metals

Chris Ulbrich, CEO

Trusted FENN for decades. Ulbrich has trusted FENN wire flattening and shaping lines for several decades to produce the highest quality shaped and flat wire available. more >

Shop for Spares & Dies

We’ve been in the business of manufacturing quality machinery since 1900, so we know what it takes to get your machine running. Ordering spare parts and accessories directly from FENN promises that you receive the correct item for your specific requirement. Don’t waste valuable time by ordering incompatible parts.

Associations

Rebuilds, Retrofits and Upgrades

For a fraction of the cost of a new machine, FENN equipment owners can increase their machine’s capabilities and stay current with safety standards, all while improving accuracy and increasing repeatability. Learn more about our rebuild, retrofit and upgrade programs >

We're Here to Help

With our comprehensive services, we are able to support our customers by telephone, digital remote capabilities, in addition to sending a service technician to your facility for diagnostics and repair.