FZ12 Video

Torsion Springs are helical springs that exert rotary force and work by twisting along their axis. Often, they are tightly wound so each coil contacts the next; when twisted, they exert a torque in the opposite direction, proportional to the amount they are twisted.

The Compression Spring is among the most basic and widely recognized types of spring. Its simplicity is its strength—it compresses and, when compressed, exerts force in opposite directions while trying to return to its original spring shape, a testament to its reliability.

Conical Springs are a type of tapered compression spring with a unique cone shape. They have a larger diameter that funnel down to a smaller diameter.

Barrel Springs start at a smaller diameter, increase in diameter at the center, and then reduce diameter again to match the starting diameter size of the spring.

Hourglass Springs are inverted barrel springs and can be designed so that each coil fits wholly or partially into an adjacent coil. Both barrel and hourglass springs are used in applications that require a low solid height, increased lateral stability, or resistance to surging.

Either type of coiling machine can make quality springs so it comes down to understanding your needs. Some things to consider are the type of springs in your workload and where you need capacity. If the requirement is for only compression springs, the dual point coiler helps to eliminate the risks associated with marking the ID of the coil. If you need to make a mixture of springs and want to change quickly from coil springs to torsion springs with some bent ends, a single point machine may offer more versatility. Another important consideration is what your production team is most comfortable with. When making springs, both types of machines offer different strengths. A blending of the two technologies is typical in most industries. We don’t believe that one technology will completely displace the other. For example, a shop may want to use dual-point machines for compression springs but may want to use single points for extension or torsion springs.

FZ-100 | Size 0

FZ-10 | Size 0

FZ-810 | Size 0-1/2

FZ-11 | Size 1

FZ-115 | Size 1-1/2

FZ-12 | Size 2

FZ-125 | Size 2-1/2

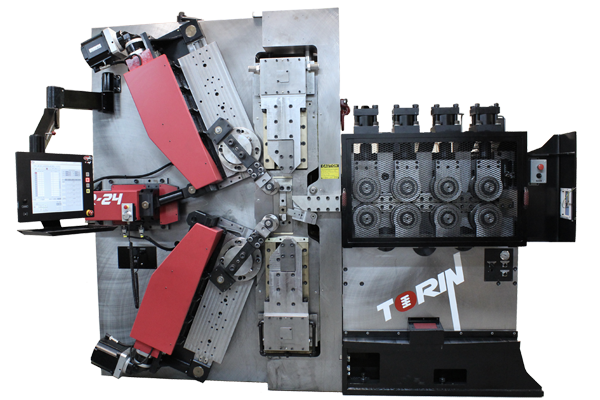

FZ-24 | Size 4

Adaptability is the key to success in today’s competitive manufacturing market. To help your business stay competitive, FENN is pleased to offer the Torin line of high-speed, versatile spring coiler machines that are now available in single- and dual-point configurations.

For decades, Torin has long been recognized as the premiere spring coiler brand. In 2003, FENN acquired the brand from BHS-Torin and continues the legacy of producing high-quality machinery made in the USA.

FENN offers single-point Torin Spring Coilers available for wire ranging from .003” to .750” in diameter. A FZ Series™ Spring Coiler can produce a variety of springs including, but not limited to, compression, extension, torsion, belting, magazine, constant force, shaped wire, wire forms, and rings.

FZ12 Video

FZ11 Video

FZ10 Video

Every Torin Spring Coiler comes standard with 4 axes, which fulfill the feed, diameter, pitch, and cut functions. For customers who require greater versatility, the torsion and lateral coiling point functions of axes can be added. These additional axes enable the production of springs such as torsion, wire forms and hooked extension springs.

| Machine Size | 00 | 0 | 0-1/2 | 1 | 1-1/2 | 2 | 2-1/2 | 3 | 4 | 5 |

| Machine Series | FZ 100 | FZ 10 | FZ 810 | FZ 11 | FZ 115 | FZ 12 | FZ 125 | FZ 23 | FZ 24 | FZ 25 |

| Wire Diameter (In) |

.003 – .015 | .008 – .028 | .010 – .040 | .015 – .080 | .032 – .135 | .047 – .177 | .080 – .275 | .125 – .375 | .160 – .625 | .250 – .750 |

| Wire Diameter (mm) |

.076 – .380 | .200 – .700 | .250 – 1.00 | .400 – 2.00 | .800 – 3.50 | 1.20 – 4.50 | 2.00 – 7.00 | 3.20 – 9.50 | 4.00 – 16.0 | 6.30 – 19.0 |

| Wire Diameter Torsion (in) |

.003 – .015 | .008 – .028 | .010 – .040 | .015 – .080 | .032 – .135 | .047 – .177 | .080 – .250 | .125 – .325 | .160 – .440 | .250 – .500 |

| Wire Diameter Torsion (mm) |

0.08 – .380 | .200 – .700 | .250 – 1.00 | .400 – 2.00 | .800 – 3.00 | 1.20 – 4.50 | 2.00 – 6.40 | 3.20 – 8.30 | 4.00 – 11.2 | 6.30 – 12.7 |

| Minimum Index | 3 | 3 | 4 | 3 | 3 | 3 | 3 | 3 | 5 | 5 |

| Spring Body Max (in) |

.281 | .875 | .875 | 1.75 | 2.25 | 3.25 | 4.25 | 5 | 6 | 10 |

| Spring Body Max (mm) |

7.1 | 22 | 22 | 44 | 57 | 83 | 108 | 127 | 152 | 254 |

| Feed Length | UNLIMITED | UNLIMITED | UNLIMITED | UNLIMITED | UNLIMITED | UNLIMITED | UNLIMITED | UNLIMITED | UNLIMITED | UNLIMITED |

The Revolution (R) Series™ utilizes the same robust mechanics and reliable, accurate controls as the FZ Series with the use of two-point coiling technology. FENN offers dual point Torin coilers available for wire ranging from .008” to .750” in diameter. Torin’s R-Series of dual point spring coiling machines can manufacture round compression and extension springs. Torin spring coilers are designed & built for fast set-up and changeover of springs with the user-friendly spring program generator.

| Machine Size | 0 | 1 | 1-1/2 | 2 | 2-1/2 | 3 | 4 | 5 |

| Machine Series | R-10 | R-11 | R-115 | R-12 | R-125 | R-23 | R-24 | R-25 |

| Wire Diameter (in) |

.008 – .028 | .015 – .080 | .032 – .135 | .047 – .177 | .080 – .275 | .125 – .375 | .250 – .625 | .375 – .750 |

| Wire Diameter (mm) |

.200 – .700 | .400 – 2.00 | .800 – 3.50 | 1.20 – 4.50 | 2.00 – 7.00 | 3.20 – 9.50 | 6.35 – 16.0 | 9.50 – 19.0 |

| Minimum Index | 3 | 3 | 3 | 3 | 3 | 3 | 5 | 5 |

| Spring Body Max (in) |

.875 | 1.75 | 2.25 | 3.25 | 4.25 | 5 | 6 | 10 |

| Spring Body Max (mm) |

22 | 44 | 57 | 83 | 108 | 127 | 152 | 254 |

| Feed Length | UNLIMITED | UNLIMITED | UNLIMITED | UNLIMITED | UNLIMITED | UNLIMITED | UNLIMITED | UNLIMITED |

Since the 1950s, Torin has been supplying Constant Force Coilers, specially designed coiling machines for manufacturing constant force springs. FENN has developed the CF-Series into reliable machines capable of making top-quality constant force springs.

As part of FENN’s unique design, the same set of feed rolls can be used for the entire range of the machine – there is no need to change rolls for varying thicknesses of material. FENN offers the complete package for your constant force coiling operation – machine, press and guiding, exit chutes, payoffs, and ovens.

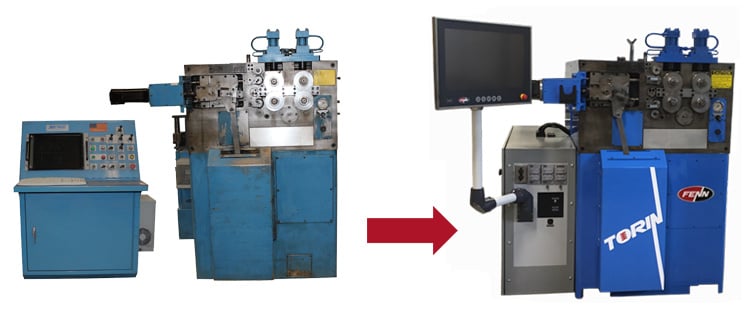

FENN’s Electrical Retrofit program provides unmatched value: our highly knowledgeable, experienced engineers and factory technicians enable us to deliver retrofitted equipment at a fraction of the cost of a new machine. Let us help you maximize the potential and output of your Torin Spring Coiler with our CNC technology, all backed by our 1 year retrofit warranty.

Control Upgrades are also available for older Torin servo-controlled spring coilers. Give your spring coiler forming machine a complete control upgrade including software with the latest FZ Series features. With this package, eliminate the risk of relying on obsolete components.

Z SERIES & CNC CONTROL UPGRADES

Control Upgrades are also available for older Torin servo-controlled spring coilers. Give your spring coiler forming machine a complete control upgrade including software with the latest FZ Series features. With this package, eliminate the risk of relying on obsolete components.

ELECTRICAL RETROFIT PROGRAM FOR MECHANICAL SPRING COILERS

Now you can benefit from maximized potential and output with our CNC technology for a fraction of the cost of a new machine. By retrofitting your mechanical Spring Coiler, you can increase your machine’s capabilities with high-quality OEM parts to keep your machine running at optimum performance. Trust our experts to provide a robust solution built to last as long as our machines do!

Don’t risk downtime!

The best service FENN can provide is preventing the need for unscheduled service.

Allow the experts at FENN to keep your machine running at the highest level of productivity.

An annual plant visit, which consists of a 50-point inspection by an OEM-certified technician, to evaluate crucial mechanical and electronic components of your machine to prevent issues before they affect your production.

Included is a detailed inspection report, providing valuable information on the condition of your machine, areas of concern and recommended repairs.

Training: Ensuring your staff is adequately trained to use the metal forming machine to its full potential.

Service: Installation of parts resulting from your initial inspection.

Repair: Resolve any additional service or maintenance issues that arise throughout the year.

Program participants receive an exclusive 15% discount on all our quality OEM spare parts.

Premium accessibility. PM customers will receive preferential treatment outside of scheduled PM visits in the service queue.

Software updates for FZ and R-Series Spring Coilers are included in the program.