Wire Flattening & Shaping Lines

Precise | Productive | Reliable | Versatile

High-speed lines that can meet aggressive machine production requirements. Achieving up to 3,000 feet per minute (15.25 mps).

More than a Century of Wire Shaping Experience

FENN has led quality wire flattening and shaping machinery for over 120 years. Our experts take the time to design and build suitable machines to fit your specifications and fulfill your unique production requirements. With experience building standard metal forming equipment and customized metal forming machinery solutions, FENN’s product and service offerings can help increase precision and productivity for your business.

Many industries across various applications trust FENN for their wire-shaping mills. We will design an effective combination of equipment to accurately and economically produce your product. From the machine’s conception and design to creating a pass schedule, developing the appropriate rolls, and implementing the proper measuring equipment, we will ensure your project is handled expertly from beginning to end. Contact us today to start a conversation and learn how quickly and accurately you can produce shaped wire!

Wire Shapes

FENN wire shaping lines are not limited to rolling natural-edged flat wire: square, rectangle, trapezoid, oval, half-round, and many other shapes can be rolled with the proper selection of equipment.

With ample experience in the fields of engineering and manufacturing metal forming machines, FENN provides state-of-the-art equipment to suit your most demanding production requirements.

Designed & Built to Maximize Productivity

FENN’s comprehensive range of wire shaping & flattening equipment is suitable for rolling both ferrous and non-ferrous metals. Each application is reviewed in detail by our experienced in-house engineering team to determine the correct arrangement or necessary equipment for each customer’s specific requirements.

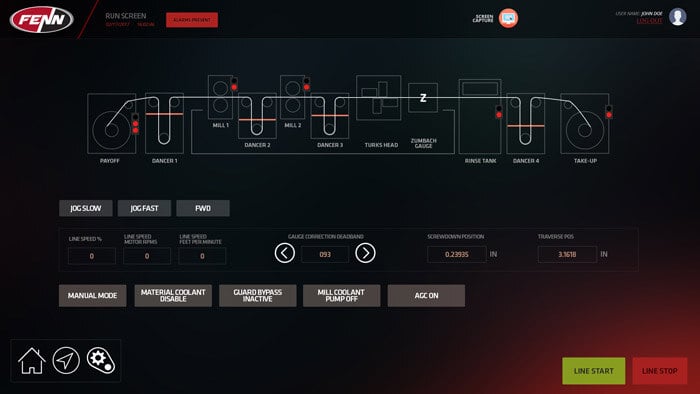

Many applications can be achieved with a single-stand, two-stand tandem, or three-stand tandem mill arrangement. For certain applications with more aggressive reductions, additional stands may be added or used in conjunction with edgers, draw blocks, pay-offs and take-ups, turks heads, dancers, and rolling mills to process the material requirements.

Features You Can Expect From FENN

- Inline pre-draw

- Speeds up to 3,000 FPM (915 MPM)

- Accurate tension and speed control

- Touchscreen HMI

- Servo traversing wind

- Lateral adjustment

- 2HI/4HI design dependent upon the application

No previous experience? No Problem.

FENN specializes in clientele with no previous wire shaping or flattening equipment experience. Let our years of experience and expertise work to your advantage! We will design an effective combination of professional equipment to produce your product accurately and efficiently. From the machine’s conception and design to creating a pass schedule, designing the appropriate rolls, and implementing the appropriate measuring equipment, we will ensure your project is handled expertly from beginning to end.

During rotary swaging, forming dies back by hammer blocks revolve around the workpiece. As the spindle revolves, centrifugal force throws the hammers and dies outwards against a series of rollers surrounding it. Each time the hammer blocks strike diametrically opposed rollers, they are driven inward, causing the die halves to close and compress the metal being swaged.

Wire Shaping Machines for These Industries

Photovoltaic Wire Line

Three wire flattening mills in tandem were used, running up to 2600 FPM (800 MPM). The line featured SPC & AGC technology along with precision, speed, and tension control to ensure high accuracy

Automotive Wire

An arrangement of both wire flattening and shaping equipment used to produce wire for collet sections

Orthodontic Wire

A turks head paired with SPC & AGC ensured precise production of wire

Wellscreen Wire

A rolling mill and turks head arrangement can be used to produce wedge shaped wire used in oil and water wellscreen production

Retaining Ring Wire

Features four rolling mills with an edger, a turks head, and speed & tension control dancers

Medical Wire Line

Processes ultra-fine medical wire used is applications such as catheter reinforcement and in stents

Customized Software

Our expert staff will develop a software package for your FENN Wire Flattening and Shaping Mill.

Typical features include:

Bring New Life to Old Machines

Do you have an older wire shaping machine or line that is not operating to its maximum potential? Have your project and production requirements changed? Does your metal forming process require updates to meet new specifications? FENN’s experienced engineering team offers a comprehensive evaluation of your equipment and will recommend an upgrade package that will ensure your equipment performs to its fullest potential.

Email sales@fenn-torin.com to learn more about our rebuild and upgrade programs.

Service & Support

FENN understands that uptime is key to your business’s productivity and profitability. We offer a full range of spare parts available for both FENN and Torin metal forming machines. With an extensive inventory, FENN can offer a wide array of parts shipped quickly to your door. Our knowledgeable staff will help to ensure you receive the necessary parts to keep your equipment running effectively with minimal downtime. Using FENN spare parts is essential to maximizing your machine’s efficiency. Don’t know exactly what you need? Our experienced staff will take the time to work with you to understand your unique requirements.

Upgrade Program for Your Aging Machinery

With a legacy of quality, reliability, and long-lasting durability, FENN has developed an upgrade program for upgrading, rebuilding, or retrofitting existing FENN equipment. Customers can maximize their machine productivity for aging equipment and extend the machine’s usable life.

We’re Here For You – Training, Support & Service

As a century-old company, we are proud of the equipment we design and build, always ensuring it meets your production requirements. We offer comprehensive training programs that can be tailored to meet your business needs. Whether you have purchased a new metal forming machine, upgraded existing equipment or your experienced staff is retiring, FENN is available to answer questions and offer training to keep your business productive. Let us know how we can help!