Renewable Energy Industry

From the copper strips used in wind turbines to the lithium strips in rechargeable batteries to the zirconium rods in nuclear cells, FENN metal forming machinery continues to play a crucial role in the renewable energy industry. For over a century, we have been engineering custom metal-forming equipment to ensure that manufacturers in the renewable energy industry have access to the high-quality machinery they need to be successful and make improvements in their production processes.

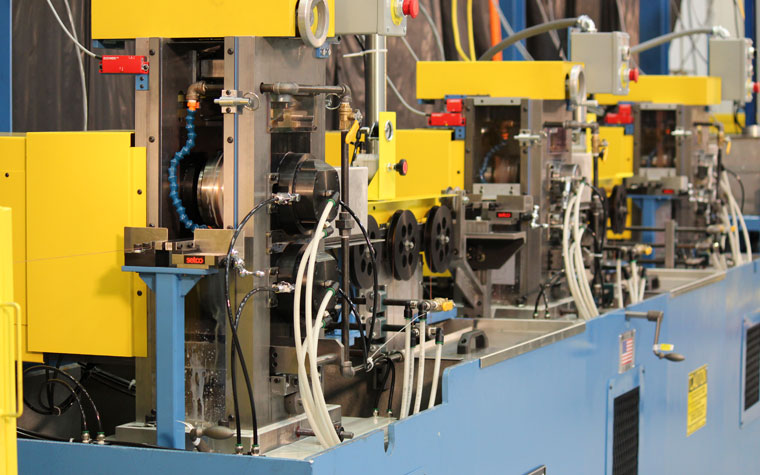

Our experts thoroughly design and build state-of-the-art machinery to fit our clients’ exact needs and specifications. In renewable energy plants across the world, our rolling mills, drawbenches, swagers, and wire flattening and shaping lines can be seen increasing production and improving the quality of the materials produced.

FENN has worked with a variety of companies in the renewable energy industry to fulfill applications relevant to:

- Solar

- Wind

- Superconducting

- Hydro

- Nuclear

- Battery power cells

- Transformer/ motor wire

To learn how our custom precision machinery can improve production speed and output quality for your renewable energy needs, contact FENN today.

FENN plays an important role in the renewable energy industry by offering customizable hot and cold rolling mills for both non-ferrous and ferrous wires or strips. For any application up to 3.3 million lbs. (1500 MT) separating force our rolling mills have been used to produce:

- Lithium strips for rechargeable batteries

- Lead strips for automotive and storage batteries

- Nickel substrate strips for alkaline batteries

Our rolling mills are available in 2Hi and 4Hi roll configurations. They may be work roll driven, back-up roll driven, or a combination of both. Custom Rolling Mill machines are FENN’s specialty, and we invite you to contact us with inquiries regarding any size and configuration. - 4HI mills with work rolls are offered as small as .500″ (12.7mm) in diameter.

- 2HI mills are offered with rolls up to 16″ (400mm) in diameter.

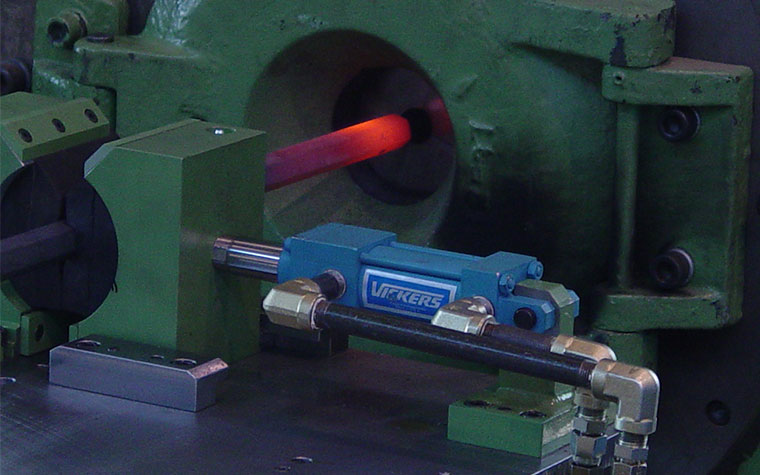

FENN Swagers are commonly used in the materials research industry to improve grain structure and finish. Swaging machines offer a cost-effective way to form and reshape wires, tubes, and rods. They are also effective metal-forming machines used in metallurgy laboratories to test and analyze alloy strength and grain structures.

Swaging improves grain structure since the reduction is by a succession of blows that do not seriously disturb the metal's molecular arrangement. This allows for a smooth-flowing rearrangement of grain. It is possible to swage material of a fragile crystalline structure to a point where it will become ductile enough to withstand severe bending. It has also been found that swaged pins and punches may have many times the wear life of a machine's part due to this grain refinement and increased density.

Swagers produce impressive force; duplicating a swagers performance with a slower force requires a punch press or drop hammer with massive proportions. For example, a small 1F swager weighing 625 lbs., can deliver the equivalent of 8 tons of force, a 3F weighing 1900 lbs. can deliver approximately 75 tons of force, and a 6F swager weighing about 10,000 lbs. can deliver an impressive 700 tons of force. Check out this video of a FENN Drawbench in action.

Swagers offer the renewable energy industry a cost-effective way to form various metal parts from tubes, wires, or rods. Swaging can be performed both hot or cold, although cold is popular because of its hardening effect on most materials. The process also improves grain structure, giving the part greater strength and an unusually fine finish.

Some examples in the renewable energy industry include:

- Zirconium rods for nuclear applications

- Superconducting materials

- Cartridge heaters used in nuclear energy

Based on a simple principle, swaging the process of shaping metal (forging) by means of a series of very rapid, blows delivered by rotating hammers and forming dies around a piece of work. It is a highly economical method to point tubing, rod, and wire for redraw, and to size, reduce, shape, taper, bond or form metal parts, hot or cold. Metal is formed – not machined – so there are no wasteful chips. Watch this video of FENN Automated NF-2 Swaging System.

Our wire flattening and shaping lines are known worldwide for their reliability, precision, and versatility which make them an asset to the renewable energy industry. Each of our wire flattening and shaping lines is created to meet the specific requirements of our customer, and they can be designed for both ferrous and non-ferrous materials. In the renewable energy industry, the work of our wire flattening and shaping lines can be seen in:

- Copper strip used in wind turbine generators

- Photovoltaic applications

- Power transformers

Learn more about FENN PV Ribbon & Busbars

Our experts thoroughly design and build state-of-the-art machinery to fit our clients’ exact needs and specifications. In renewable energy plants across the world, our rolling mills, drawbenches, swagers, and wire flattening and shaping lines can be seen increasing production and improving the quality of the materials produced.

FENN has worked with a variety of companies in the renewable energy industry to fulfill applications relevant to:

- Solar

- Wind

- Superconducting

- Hydro

- Nuclear

- Battery power cells

- Transformer/ motor wire

To learn how our custom precision machinery can improve production speed and output quality for your renewable energy needs, contact FENN today.

-

ROLLING MILLS

- Lithium strips for rechargeable batteries

- Lead strips for automotive and storage batteries

- Nickel substrate strips for alkaline batteries

Our rolling mills are available in 2Hi and 4Hi roll configurations. They may be work roll driven, back-up roll driven, or a combination of both. Custom Rolling Mill machines are FENN’s specialty, and we invite you to contact us with inquiries regarding any size and configuration. - 4HI mills with work rolls are offered as small as .500″ (12.7mm) in diameter.

- 2HI mills are offered with rolls up to 16″ (400mm) in diameter.

-

DRAWING EQUIPMENT

-

SWAGER MACHINES

- Zirconium rods for nuclear applications

- Superconducting materials

- Cartridge heaters used in nuclear energy

-

WIRE SHAPING LINES

- Copper strip used in wind turbine generators

- Photovoltaic applications

- Power transformers

FENN plays an important role in the renewable energy industry by offering customizable hot and cold rolling mills for both non-ferrous and ferrous wires or strips. For any application up to 3.3 million lbs. (1500 MT) separating force our rolling mills have been used to produce:

FENN Swagers are commonly used in the materials research industry to improve grain structure and finish. Swaging machines offer a cost-effective way to form and reshape wires, tubes, and rods. They are also effective metal-forming machines used in metallurgy laboratories to test and analyze alloy strength and grain structures.

Swaging improves grain structure since the reduction is by a succession of blows that do not seriously disturb the metal's molecular arrangement. This allows for a smooth-flowing rearrangement of grain. It is possible to swage material of a fragile crystalline structure to a point where it will become ductile enough to withstand severe bending. It has also been found that swaged pins and punches may have many times the wear life of a machine's part due to this grain refinement and increased density.

Swagers produce impressive force; duplicating a swagers performance with a slower force requires a punch press or drop hammer with massive proportions. For example, a small 1F swager weighing 625 lbs., can deliver the equivalent of 8 tons of force, a 3F weighing 1900 lbs. can deliver approximately 75 tons of force, and a 6F swager weighing about 10,000 lbs. can deliver an impressive 700 tons of force. Check out this video of a FENN Drawbench in action.

Swagers offer the renewable energy industry a cost-effective way to form various metal parts from tubes, wires, or rods. Swaging can be performed both hot or cold, although cold is popular because of its hardening effect on most materials. The process also improves grain structure, giving the part greater strength and an unusually fine finish.

Some examples in the renewable energy industry include:

Based on a simple principle, swaging the process of shaping metal (forging) by means of a series of very rapid, blows delivered by rotating hammers and forming dies around a piece of work. It is a highly economical method to point tubing, rod, and wire for redraw, and to size, reduce, shape, taper, bond or form metal parts, hot or cold. Metal is formed – not machined – so there are no wasteful chips. Watch this video of FENN Automated NF-2 Swaging System.

Our wire flattening and shaping lines are known worldwide for their reliability, precision, and versatility which make them an asset to the renewable energy industry. Each of our wire flattening and shaping lines is created to meet the specific requirements of our customer, and they can be designed for both ferrous and non-ferrous materials. In the renewable energy industry, the work of our wire flattening and shaping lines can be seen in:

Learn more about FENN PV Ribbon & Busbars