How to Optimize Your Production Line With FENN-Torin’s Spring Coilers

Efficiency is the currency of modern manufacturing. For engineers and operations managers, even small gains in throughput—and reductions in waste—can translate to substantial cost savings, higher margin, and a stronger competitive edge. In industries where spring coiling machinery is central, Fenn-Torin’s spring coilers offer proven ways to address key inefficiencies on the production line. Read on to learn how these machines deliver measurable gains, real-world savings, and why so many manufacturers trust Fenn-Torin as their spring-coiling partner.

Why Production Inefficiencies Happen — And What They Cost You

Before we dive into what Fenn-Torin’s spring coilers do differently, it helps to understand the kinds of problems they’re solving, and the stakes involved.

- Downtime & Changeovers: Frequent coil size or material changes require tooling, setup, and calibration—all of which eat into productive time.

- Material Waste & Rework: Inaccuracies in coiling (pitch, diameter, tension) lead to scrap, rework, or outright part rejection.

- Bottlenecks in Throughput: If your coiler can’t keep up with feeding, cutting, or downstream operations, that underutilizes other machinery and labor.

- Maintenance & Unplanned Failures: Poorly designed or unreliable coilers contribute to wear, unexpected breakdowns, and repair costs.

Individually, each of these can add up. Collectively, they erode profitability and hinder your ability to scale production reliably.

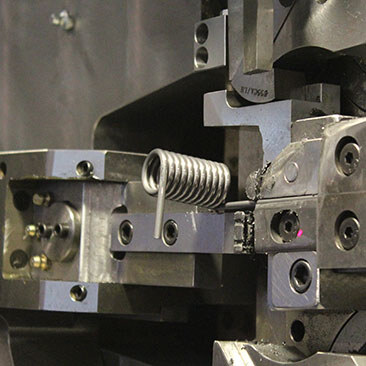

How Fenn-Torin’s Spring Coiling Machines Solve These Inefficiencies

Fenn addresses these challenges head-on with design, engineering, and control systems that are optimized for reliability, accuracy, and efficiency.

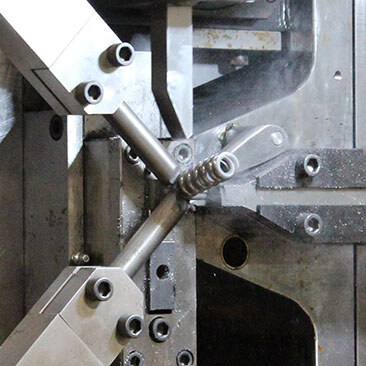

1. Rapid, Precise Setup & Changeover

- Modular tooling components that allow for quick swap-out of coiling points, guides, and arbors.

- Pre-set parameters and memory profiles so different coil types or sizes can be recalled, reducing calibration time.

- Robust fixturing and alignment built in, so when a tool is changed, alignment is accurate immediately—without lengthy trial runs.

2. Tight Control of Coil Geometry & Material Use

- Closed-loop feedback systems that monitor diameter and spring length in real time. Deviations are corrected automatically.

- Precision motion control components—servo motors, low backlash gearboxes, high-quality bearings—to ensure consistent performance even under heavy use.

- Material handling features (guides, tensioners, payoffs) that reduce surface damage, deformation, or misfeeds.

3. Enhanced Throughput, Fewer Bottlenecks

- High speed coiling capability paired with load balancing so the coiler can match upstream (wire draw, material feed) and downstream (cutting, heat treatment) rates.

- Reduced scrap and reruns, which means fewer stoppages for clean-ups and material replacement.

- Designed for straight forward, preventative maintenance (easy access to grease fittings, modular parts for wear components) so downtime for servicing is minimized.

4. Built-in Reliability & Low Maintenance Burden

- Heavy-duty components rated for long life in industrial settings.

- Accessible design for parts prone to wear, so replacements are easier and maintenance intervals are predictable.

- Support, training and retrofit or upgrade options from FENN- Torin, so machines evolve rather than age into obsolescence.

Quantified Savings: Time, Waste and Cost

Clients who integrate FENN- Torin’s spring coilers into their production lines consistently report significant gains. Many see a 30 to 60 percent reduction in setup and changeover time, allowing operators to dedicate more hours to productive work. Material waste is often reduced by 20 to 30 percent thanks to tighter tolerances and improved handling. Throughput can increase by as much as 15 to 40 percent, while unplanned downtime drops substantially. These combined improvements mean many customers recoup the capital cost of a new or upgraded coiler in as little as 12 to 18 months.

Why FENN- Torin Is the Go-To Partner for Spring Coiling Machinery

It’s not just what the machines do, but how they’re delivered that matters. For manufacturing engineers and operations managers, reliability, long-term support, and customization are crucial.

- Tailored Engineering: FENN-Torin works with you to match coil size ranges, materials, production speed, and downstream operations.

- Support and Training: Proper operator and maintenance training is included, helping avoid typical mistakes that degrade performance.

- Upgrades and Retrofits: Existing lines can often be upgraded with newer control systems, improved tooling, or enhanced automation rather than replaced.

- Proven Quality: Built with industrial-grade components, designed for long life, with real feedback loops and continuous improvement.

Learn How FENN-Torin Can Optimize Your Production Line!

Optimizing your production line isn’t about one big change—it’s about identifying inefficiencies, applying targeted solutions, and working with equipment that’s both engineered to high standards and supported after installation. FENN- Torin’s spring coiling machinery delivers measurable improvements in time, waste, cost, and throughput. For manufacturing engineers and operations managers aiming to sharpen efficiency, reduce waste, and scale reliably, FENN-Torin is more than a supplier—it’s a partner in performance.

If you’re ready to explore how FENN-Torin spring coilers can upgrade your production line, contact us today. Let’s define your goals, map your baseline, and build a solution that makes efficiency your standard.