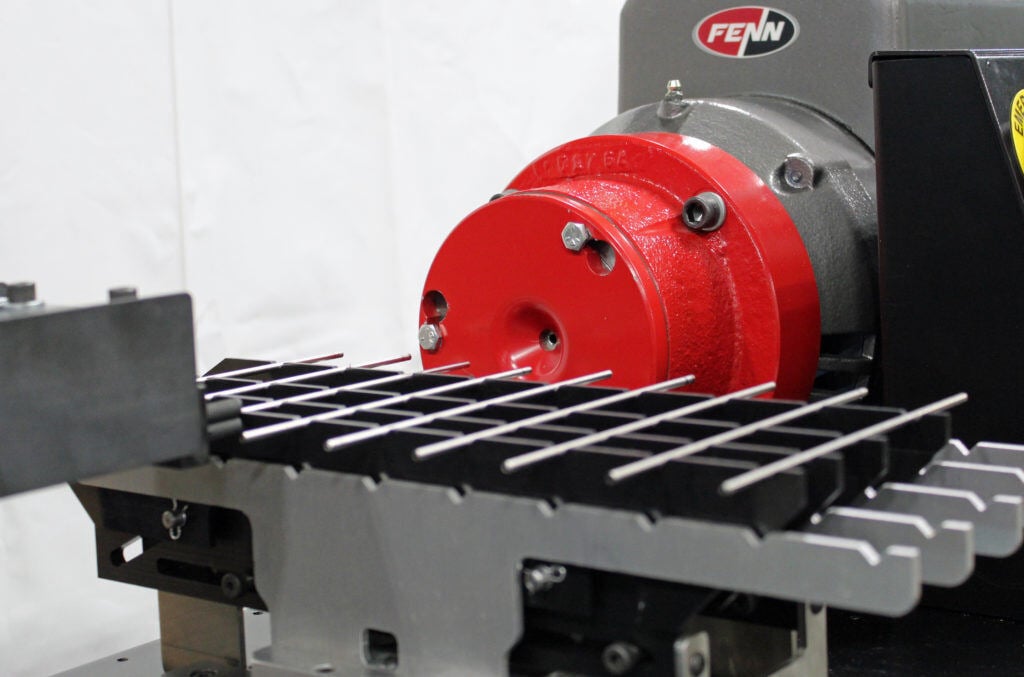

Understanding Turks Heads: How They Shape and Control Wire and Tube Products

In wire and tube manufacturing, precision is everything. Whether you’re producing round wire, square tubing, custom-shaped profiles, or tightly controlled flat wire, you need equipment capable of forming material accurately and consistently. Turks Heads are one of the most essential forming tools in this process, offering unmatched control over size, shape, and surface quality. Their versatility makes them a critical component for manufacturers across automotive, aerospace, electronics, energy, medical, and consumer goods markets.

If you’re exploring ways to improve your forming operations—or simply want to better understand how these machines work—this guide breaks down everything you need to know about Turks Heads and how they shape wire and tube products with exceptional precision.

What Is a Turks Head?

A Turks Head is a metal forming machine used to shape wire, rod, strip, and tube into uniform profiles. Unlike rolling mills that rely on rotating rolls positioned above and below the material, Turks Heads use rolls arranged around the material—typically in a four-roll configuration—to create a fully enclosed forming zone.

This design provides excellent dimensional control because the material is shaped from all sides simultaneously. Manufacturers depend on Turks Heads for:

- Producing square, rectangular, and custom profiles

- Controlling width, thickness, and corner radii

- Achieving tight tolerances and consistent surface finish

Because they are both adaptable and accurate, Turks Heads are used as standalone units or as part of integrated production lines.

How Turks Heads Work

Turks Heads function by feeding material through a set of rolls arranged horizontally and vertically. These rolls are manually or automatically adjusted to achieve the precise shape desired. As the material passes through the enclosed forming box, pressure is applied evenly across all sides.

This process:

- Reduces and reshapes the cross-section

- Controls edge geometry and flatness

- Ensures dimensional uniformity

The enclosed roll design makes Turks Heads ideal for applications where tight tolerances and repeatability are essential.

Types of Turks Heads and Their Applications

Different forming needs require different machine configurations. The most common styles include:

Universal Type Turks Heads

Universal type Turks Heads are used for shaping material into square or rectangular cross-sections. Universal type Turks Heads use two adjusting screws – to position the four rollers as necessary to achieve the desired cross-section dimensions.

Plain Type Turks Heads

Plain type Turks Heads are used for shaping material into complex cross-sections, such as diamond or wedge shapes. Plain type Turks Heads use four adjusting screws – each of the four forming rollers is positioned by its own adjusting screw.

Combination Type Turks Heads

Combination type Turks Heads may be used to shape material into both square/rectangular, and also into complex cross-sections. Combination type Turks Heads feature six adjusting screws. Four adjusting screws are used to position the rollers in a plain-style configuration – and two additional adjusting screws allow the operator to switch between plain-style rolling, and universal-style rolling.

Benefits of Using Turks Heads in Wire and Tube Production

Turks Heads provide a range of performance and quality advantages that other forming equipment may not achieve alone.

1. Superior Dimensional Control

The fully enclosed forming zone ensures consistent shaping from all four sides, resulting in exceptional precision.

2. Versatility Across Shapes and Materials

Whether forming square, rectangular, flat, or specialty shapes, Turks Heads handle a wide range of profiles and metals.

3. Increased Production Efficiency

Once set, a Turks Head runs continuously with minimal adjustment, improving throughput and reducing operational downtime.

4. Enhanced Straightness and Surface Quality

The rolling action naturally straightens wire and improves surface uniformity, producing a cleaner finished product.

5. Integration with Rolling Mills

Turks Heads often work downstream from rolling mills to refine dimensions after initial forming. FENN’s rolling mills and Turks Heads can be integrated into a seamless production line for maximum control.

Why Choose FENN Turks Heads?

FENN has been an industry leader in metal forming solutions for over a century. Our Turks Heads are engineered to provide reliability, precision, and long-term durability. With highly adjustable roll settings, robust construction, and custom engineering capabilities, FENN Turks Heads support manufacturers with:

- Repeatable accuracy

- Long lifespan and rugged performance

- Easy integration with existing equipment

- Custom roll designs for unique profiles

- Experienced engineering and technical support

FENN also provides complete turnkey systems when customers require coordinated rolling mills, Turks Heads, coilers, payoff equipment, and more.

To learn more about Turks Heads or to discuss your project requirements, contact FENN’s engineering team. We can help design a custom metal forming solution tailored to your needs.