Engineers Week: Interview with Jack & Jake

Join us in Reimagining the Possible

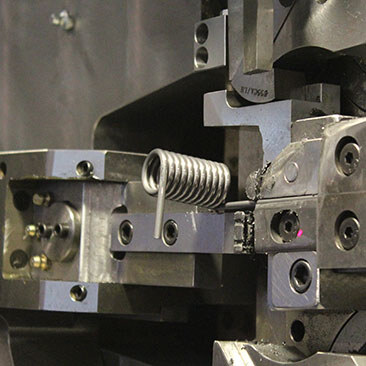

Its engineering week, and we could not do our job at FENN without our engineers. There are many aspects that go into running this business, but there must be people who can take an idea, think freely & run with it. We start at the application, then our engineers take a customer’s specifications and create a machine that will exceed their expectations.

We had two of our engineer’s, Jack Henne- Senior Engineer and Jake Skowronek- Mechanical Engineer, answer a few questions in hopes to inspire someone who may be interested in the engineering and give a little insight into their roles.

- Question “What made you choose engineering?”

- Jack- I had the knack. One of my first toys was a “Mr. Machine,” a wind up “robot” with gears and eccentrics that could be disassembled and put back together. At about 3-4 years old, one of my favorite things to do was to disassemble the doorknob and latch on the back door entry, to my mother’s dismay. By five, I could put it all back together.

- Jake- I chose engineering because I was always interested in machinery and mechanisms. I have also always enjoyed woodworking and building things and believed being a design engineer would bring me the same type of enjoyment.

- Question “What does your typical day look like?”

- Jack- Most engineers, especially in small companies, do not have a typical day. If you want every day to be like the one before it, do not go into engineering, maybe try working for an insurance company in a non-technical role. Typical things that an engineer may do in any given day are:

- Work with customers to determine their design needs for new product design.

- Design an assembly in CAD, analyze the motions to determine suitability, run FEA to analyze stresses and deflections.

- Check tolerances and fits on drawings.

- Create specifications for new product design and later for presentation to the market space.

- Review machining errors on manufactured parts to determine if the part should be scrapped, used as is, or how to modify to make it suitable.

- Review and test operation of new equipment or new uses of existing equipment and make changes where appropriate.

- Finding previous designs that may be helpful on the beginnings of a modern design.

- Determine suitable alternatives on older, but still active, designs where materials or processes are no longer available.

- Jake- My typical day mostly consists of working on designs and creating detailed part and assembly drawings. It also often consists of addressing questions or concerns from vendors making our parts, or the assembly team, as they assemble machine components we have designed.

- Question “What is your favorite part about being an engineer?”

- Jack- I enjoy figuring out how to do something. For me, a home run on a redesign project is to make it work better than before, make it do things that were not possible before, and most importantly make it cost less than before.

- Jake- My favorite part about being an engineer at Fenn is being able to go out to the shop floor and see the final product. To see a design concept, go from a computer screen to reality, often in just months, has been one of the parts of the job I most enjoy.

- Question “What advice could you give to someone looking to get into engineering?”

- Jack- You need to be good in math and science, but do not assume you will not need effective communication skills. Nikola Tesla is a good example. He was a much better inventor than Westinghouse, but Westinghouse was much more successful because he could communicate his ideas much better.

- Jake- My advice would be to talk with experienced engineers as much as possible, as they have a tremendous wealth of knowledge to share and almost always enjoy doing so.

Engineering is Multi-Faceted

From speaking with customers to verify design, getting feedback from users and trainers early during the design process to maximize usability of the equipment, training users for the equipment, and having discussions internally with other engineers, designers, or manufacturing & assembly employees; Jack says these skills are all a part of the process. Communication is key with everyone involved to make sure the project moves forward without a hitch. Jack also mentions to be ready to drop everything that you intended to do that day and tackle the latest hot issue at hand when it comes up. Working together is key to being a successful engineer & FENN hopes we were able to motivate someone to think about pursuing engineering for their career path.