What is a Drawbench, and How Do They Work?

Drawbenches are a type of metal forming machine that are used for the cold drawing of a variety of different types of metal rods or tubes.

How Does A Drawbench Work?

Drawbenches work by pulling a piece of material through a die (smaller in diameter than the material), forcing it to take on the size and shape of the die as it passes through.

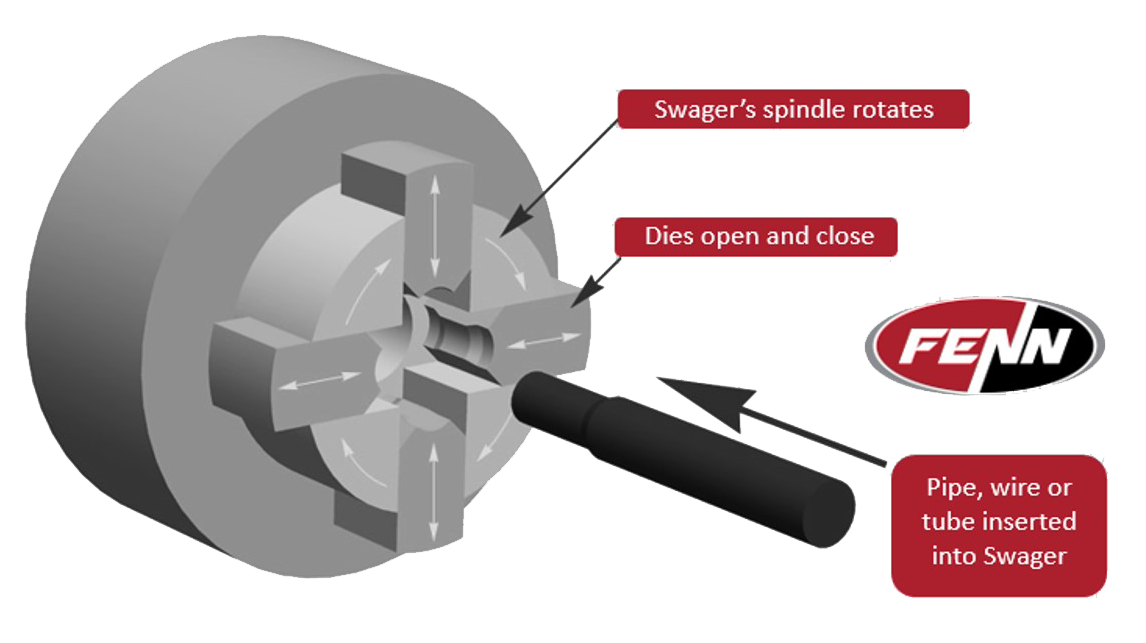

The first step in the drawing process is to point or swage the end of the material. A swager or roll pointer is used to shape the end of the material into a point. This is done because the diameter of the die is smaller than the material itself. The end of the material first needs to be small enough to fit through the die. Once the pointed end is pulled through the die, a gripper is used to grab onto it (manual grippers are used for smaller drawbenches with small amounts of pull, whereas hydraulic grippers are used for larger drawbenches with greater amounts of pull). Once the gripper has a hold of the material, the drawbench can pull (force) the material through the die, causing the metal rod or tube to take on the diameter of the die. If a tube is being drawn, a floating plug or mandrel can be used inside of it to help maintain a consistent inner diameter and wall thickness.

The lubrication used on a drawbench depends heavily on the material being processed. For some materials, dry soap drawing may be preferred, while other materials may require wet lubrication.

For smaller drawbenches, the material can be lifted out of the machine by an operator. There are often fully automated material handling systems for larger drawbenches that drop the material into a collection area.

Hydraulic vs. Chain-Driven Drawbenches

The material is pulled through the die by either a hydraulic cylinder (hydraulic drawbench) or a continuous chain (mechanical, chain-driven drawbench). Hydraulic drawbenches are beneficial as they provide a method of pull directly in line with the material allowing as clean a pull as possible but are generally favored for applications that involve shorter lengths of material. This is because the hydraulic apparatus within the drawbench essentially doubles the length of the machine, automatically making it larger and longer. As with many manufacturers, floor space could quickly become an issue as the machine gets larger. For longer lengths of material, chain-driven drawbenches are often chosen because the chain-pulling mechanism does not increase the length of the drawbench by very much. So, for example, a drawbench that needed to be 40 feet long would probably be designed as a chain-driven bench (instead of a hydraulic bench), not to increase the length significantly more.

How Does Their Size Range Compare?

Drawbenches can come in all different shapes and sizes, ranging from just a few feet long and a couple of hundred pounds of pulling force to over 200 feet long and over 200,000 pounds of pull.

While other types of drawing exist, drawbenches are generally preferred for either:

- Straight pieces of precious metals or special materials.

- Where mass production is not required, or straight lengths are more convenient than coils for the user.

Single vs. Multi-Draw Configurations

Drawbenches can be manufactured in a single-draw or multi-draw configuration. In a single-draw configuration, only one length of tube or rod can be processed at a time. The material must be removed before a new piece can be set up for drawing again.

A multi-draw drawbench has more than one draw station within the same machinery frame. The draw stations may be the same or set up as a progressive draw operation. The benefit of having a multi-draw drawbench is that a single operator can run all of the draw stations within the same machine, making the operation more efficient by requiring less labor.

What Types of Applications Are They Used For?

Because there is little waste involved and smaller lengths can be processed, drawbenches are favored for special applications where expensive materials or small amounts of materials are used (compared to a production scenario). Common applications include precious metals, superconducting, or medical applications. Drawbenches may also be used in materials research, where scientists or metallurgists are interested in how the material behaves and changes when processed by the drawbench.

To learn more about hydraulic or chain-driven drawbenches, contact the experts at FENN, builders of customized metal forming machinery, at sales@fenn-torin.com or visit https://www.fenn-torin.com/metal-forming-machines/drawing-equipment/.