Torin’s Latest Coilers

Speed, Precision, & Innovation

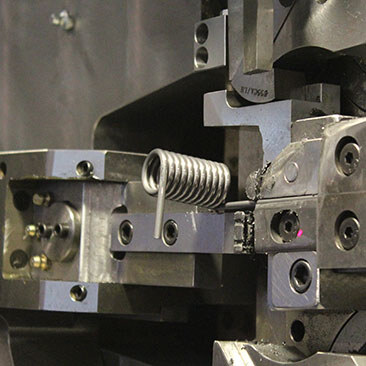

With a 120-year legacy in providing quality metal forming machinery, FENN is dedicated to improvement and innovation. Expanding the existing offerings of Torin’s FZ-generation of coilers, FENN is pleased to offer the newly redesigned FZ-100, FZ-10, and FZ-810 single point coilers (Torin also offers dual point coilers!). During the engineering phase, FENN’s team created the coilers with new motors allowing for greater torque to inertia ratio – which enables faster production rates while keeping the consistent accuracy expected from a Torin. The new design not only looks great, but also includes integrated guarding for operator safety and are competitively priced. With technology constantly evolving, FENN equipped the new coilers with updated, faster computer processing to accommodate a diverse range of coiling requirements. Implemented on all coiler models, Torin’s latest software combines many high-tech features paired with its classic CNC style programming, making training easy for current Torin operators. All of FENN’s Torin coilers are designed and proudly built in CT, USA.

FZ-100 Torin Spring Coiler

In a world where technological advancements have been at the forefront of society, FENN has received numerous requests for an FZ-generation 100-sized Torin spring coiler. As technology advances, the market looks to produce springs that are smaller and smaller. Torin’s FZ-100 model has a wire diameter range of .003” to .015” (.076 – .38mm). Existing Torin customers who run wire with diameters on the smaller end of the FZ-10 capabilities, may find that running their production on an FZ-100 model coiler will provide better results. This model is the smallest coiler offered under the Torin brand and is capable of holding very tight tolerance, which is key when it comes to producing springs or rings for micro-electronics and medical applications. The FZ-100 is the most cost-effective option for businesses looking to produce only small springs or rings.

FZ-10 Torin Spring Coiler

First making its debut at the 2019 SMI show in Pittsburgh, PA, the second generation FZ-10 Torin coiler can produce over 100,000 PPH and is available in four, five, or six axes. Wire diameter capabilities for the FZ-10 range from .008” to .028” (.20 – .70mm). This sized coiler is commonly used to produce dental arches, small springs for automotive, medical, and consumer industries, as well as rings. The Gen. 2 FZ-10 is gaining traction with customers looking to coil wire that is smaller than the capabilities of the FZ-11. With an attractive price tag, the new FZ-10 boasts a smaller footprint than the first generation FZ-10, making it an ideal size for an addition to any spring shop. Although the machine is physically smaller than its predecessor, it offers the same wire size capabilities, making it a great option for smaller wire and spring applications.

Wire diameter capabilities for the FZ-10 range from .008” to .028” (.20 – .70mm). This sized coiler is commonly used to produce dental arches, small springs for automotive, medical, and consumer industries, as well as rings. The Gen. 2 FZ-10 is gaining traction with customers looking to coil wire that is smaller than the capabilities of the FZ-11. With an attractive price tag, the new FZ-10 boasts a smaller footprint than the first generation FZ-10, making it an ideal size for an addition to any spring shop. Although the machine is physically smaller than its predecessor, it offers the same wire size capabilities, making it a great option for smaller wire and spring applications.

FZ-810 Torin Spring Coiler

While the FZ-11 has traditionally been Torin’s most popular model, the Torin 810 model coiler has been brought back by popular demand! Previous generations of the Torin 810 model size coiler were built with a hydraulic cut. As part of the redesign, FENN is incorporating a servo motor-driven cut as is now standard with the complete line of Torin coilers. The newly designed FZ-810 is capable of coiling wire ranging from .010” to .040” (.25 – 1.0mm). Although, the FZ-810 coiler can handle a larger wire diameter than the FZ-10, the machine’s footprint matches that of the smaller FZ-10 model. FENN has been approached by numerous customers requesting the 810 model be designed and sold as a member of the FZ-Series. This “in-between” coiler is compatible for wire diameters that range between the FZ-10 and FZ-11 models, with a range of .010” to .040” (.25 – 1.0mm). For customers exclusively coiling on the larger end of an FZ-10, the FZ-810 could prove to be a more cost-effective option rather than. Similarly, to the FZ-10, the FZ-810 coiler is also commonly used to produce dental arches, small springs for automotive, medical, and consumer industries, as well as rings. Customers wanted a coiler that could handle slightly larger wire than the FZ-10 is capable of. Not only was this redesign driven by requests of new customers, but existing Torin customers with the first generation Torin CNC-810 coiler were looking for this size to be offered in the new FZ-generation. Although the FZ-810 has undergone many upgrades throughout this redesign, current 810 operators will be pleased to know that existing tooling can be used on the new generation – there is no need to waste the tooling you already have.

CF-Series of Constant Force Spring Coilers

Torin produces an array of CF-Series coilers, covering a material range of .005” thick by.250” wide to .040” thick by 2.00” wide. The specially designed CF-Series coiler is used for manufacturing constant force springs, a unique type of spring that applies even torque at any extension. FENN’s design of the constant force machine ensures parallelism of the feed rolls to maintain material alignment during production. As part of FENN’s unique design, the same set of feed rolls can be used for the entire range of the machine – there is no need to change rolls for varying thickness of material. Industries, including consumer, automotive, and hardware, rely on quality constant force springs for a variety of applications. For flexibility and ease of use, the Torin CF-Series of coilers can be fed from both the left and right-hand sides of the machine. FENN can design and customize a press station to accommodate die sets for customers looking for the complete forming process.

When you purchase a Torin coiler, you’re not only buying a machine – you’re making an investment in a trusted brand. At FENN, we understand that purchasing new equipment can be a daunting decision. However, we strive to make the process a little easier by including many added conveniences, such as multiple sets of tools and training with the purchase of every new machine. Choose training at your facility or ours! FENN stands behind the quality and workmanship of new machines – providing a 2-year warranty on all new spring coilers. We know that questions come up and issues arise, which is why we make support a priority. From remote access support & diagnostics over the internet to onsite service calls and complimentary phone support, our team of local, factory trained service technicians are here to maximize your uptime & productivity. Contact us today to learn which Torin coiler is the best fit for your operation! sales@fenn-torin.com