How Steel Cold Rolling Mills Works (The Cold Rolling Process)

Did you know in 2023, domestic raw steel production is at about 1,654,000 net tons?

Comprising primarily of carbon and iron, steel is a popular metal for manufacturing applications. You’ll find buildings, tools, vehicles, airplanes, and more made from it.

Before using steel in various applications, it must undergo the rolling process. However, not all steelmaking rolling processes involve heating. You can opt for cold rolling. It’s often performed at room temperature.

What Is Cold-Rolled Steel?

Cold-rolled steel is a type of steel that has undergone further processing after the initial hot-rolling process. Once the steel undergoes hot rolling, you need to cool it with a finishing technique that lets you compress it using rollers at a relatively low temperature.

After cold rolling, the steel may be further processed through annealing or temper rolling.

The Benefits of Cold-Rolled Steel

Cold-rolled steel provides the quality and performance you need, from improved surface finish to increased strength and durability. Benefits include:

Greater Strength

Cold-rolled steel is about 20% stronger than hot-rolled steel. When you pass the steel through rollers at low temperatures, it hardens and strengthens it. This makes it ideal for use in high-stress applications.

Better Surface Finishes

Steel from cold rolling mills has a smoother and more uniform surface finish. Additionally, the cold rolling process helps to remove surface impurities. As a result, it can have a cleaner surface that’s less susceptible to corrosion and rust.

Higher Precision

Cold-rolled steel is processed at room temperature or below. This results in a more consistent and precise dimensionality compared to hot-rolled steel. You can use it to create components with tight tolerances that require little or no secondary processing.

The improved surface finish of cold-rolled steel can also contribute to higher precision in component manufacturing. A smoother surface reduces friction and wear during the forming process. This results in more consistent and precise dimensions.

Versatile

There are several options when creating cold-rolled steel. These include full-hard, quarter-hard, skin-rolled, and half-hard. Your choice of the cold-rolling process depends on the specific properties needed for the final product and the available equipment and resources.

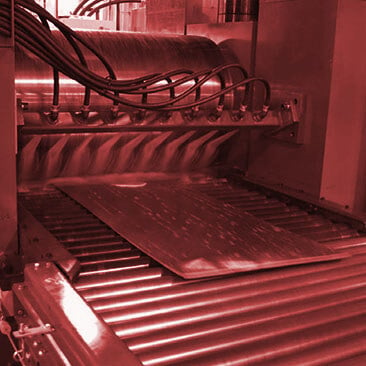

How Cold Rolling Is Done

Unlike hot rolling, which involves heating metal to high temperatures before rolling, cold rolling is done at room temperature. Need to produce cold-formed steel? Here are the basic steps involved in the cold rolling process:

Step 1: Cleaning

To start, dirt, oil, or rust is removed from the metal’s surface to ensure the metal itself is free of particles that may get in the way of the final product quality.

Step 2: Reheating

Smelt the raw steel in a large furnace to produce liquid steel. This process extracts metal from its ore and makes it easier to shape.

Step 3: Rolling

Allow the liquid steel to cool slightly before feeding it through a series of rollers. As the rollers compress the steel, it becomes thinner and stronger.

Step 4: Annealing

You may need to anneal or heat-treat the metal to improve its ductility and reduce its hardness. Annealing enhances the metal’s grain structure, making it more uniform and reducing the risk of cracking or other defects.

Step 5: Finishing

After rolling the steel to the desired thickness, it may undergo additional processing. This helps improve its surface finish.

Step 6: Inspection

Check the final product for defects and inconsistencies. This guarantees top quality before the metal goes in for production.

Produce Premium Cold-Rolled Steel

To form high-quality cold-rolled steel, you need a cold-rolling mill. At FENN, we engineer and manufacture custom rolling mills for cold rolling processes. Our team will help streamline your operations and increase productivity.

To discuss your cold-rolling needs, contact FENN today to learn more about how we can help with your manufacturing needs.