What is a Wire Pay-Off System? Wire Pay-Off Machines Explained

The wire pay-off system is critical in the manufacturing and processing industries. Its primary function is to facilitate seamless wire handling, minimize the risk of entanglements, and enhance overall productivity. Managing extensive, complex wires would pose a significant logistical challenge without these systems.

Understanding Wire Pay-Off

Wire Pay-Off Systems represent a significant advancement in wire handling technology. At their core, these systems are engineered to enhance efficiency in managing wires.

Historically, wire handling was laborious and time-consuming. However, Wire Pay-Off Machines have revolutionized this process. These machines offer unparalleled precision in managing even the most delicate wires, ensuring smooth, uninterrupted operations and significantly boosting manufacturing floor productivity.

Beyond precision, Wire Pay-Off Systems play a crucial role in reducing wire tangles, a common challenge in wire handling. This improvement alone substantially impacts daily operations, providing an automated solution to what was once a disorderly, human-dependent task.

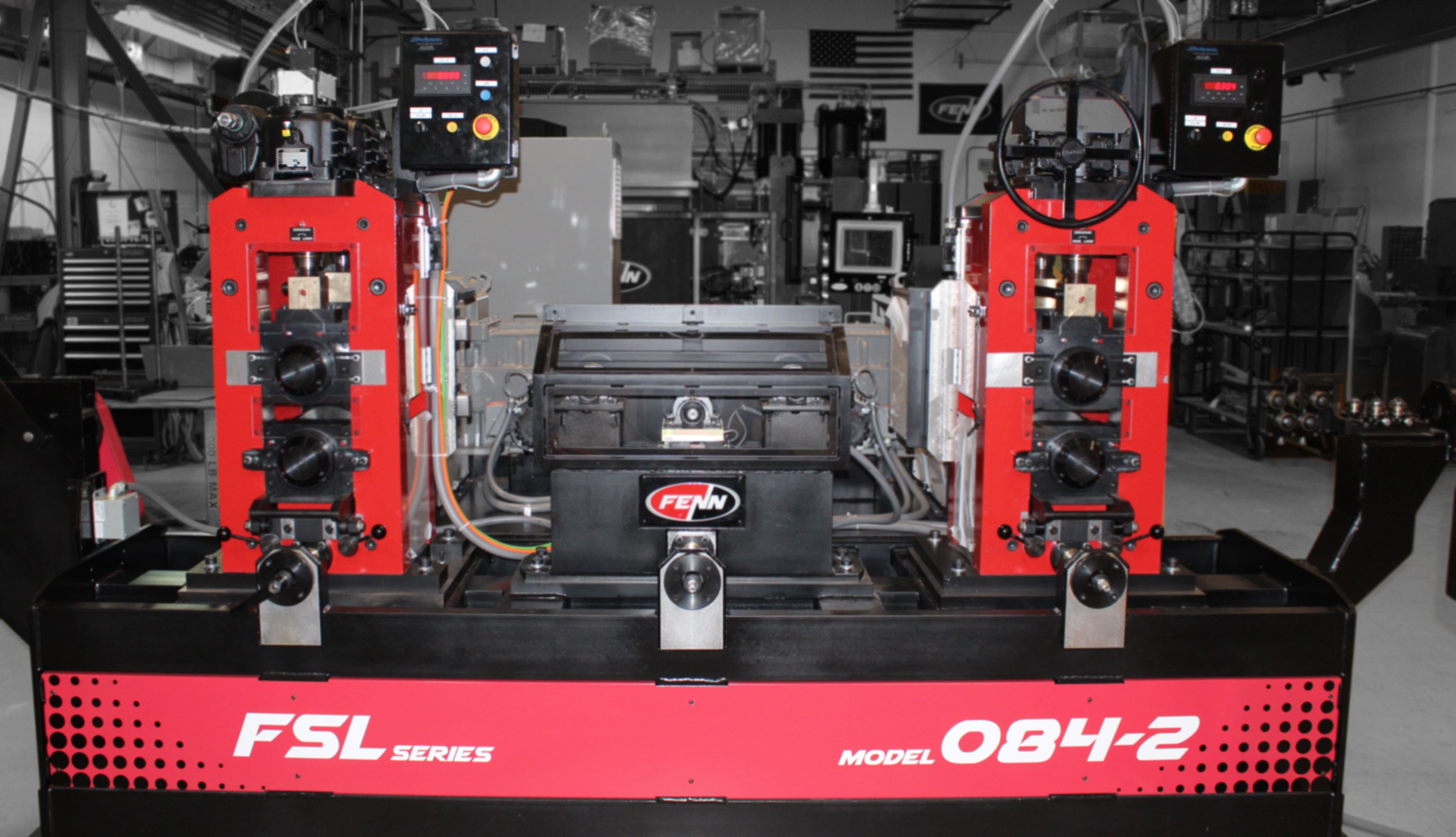

Components of a Wire Pay-Off System

The wire spool holder is a critical element of most wire pay-off machines. It is where the wire is stored before being fed through the system. The design of the spool holder typically facilitates straightforward wire loading and unloading, enabling seamless transitions between different wire materials or sizes.

Another vital component is the wire tensioner mechanism. Maintaining appropriate wire tension is essential to prevent overlapping or tangling, preserve the wire’s original form, and prevent operational mishaps.

Additionally, Wire Pay-Off Systems are equipped with user-friendly control panels. These operative controls enable system monitoring, adjustments to wire speed, and the ability to pre-set system operations, allowing for customization of each process to meet specific end-product requirements.

These integral parts function in unison within a Wire Pay-Off Machine, ensuring an efficient, consistent, and reliable wire handling experience.

Types of Wire Pay-Off Machines

There are two types of wire pay-off machines: static and dynamic. The static Wire Pay-Off Machine is characterized by its simplicity, focusing on cost-effectiveness and straightforward operational capabilities. It is ideally suited for smaller-scale production requirements where maximum efficiency and processing speeds are not critical considerations.

The dynamic Wire Pay-Off Machine is tailored for higher-scale production operations. It features precision engineering and advanced control panels capable of simultaneously managing speed and tension. This machine is renowned for achieving high feed rates while maintaining wire quality.

The Importance of Wire Pay-Off in Wire Processing

With their speed and tension controls, Dynamic Wire Pay-Off Machines deliver consistent wire dispensing. This consistency reduces wire damage risk and improves product quality. Additionally, these systems can significantly decrease labor for managing large wire reels, boosting production efficiency.

For smaller operations, static Wire Pay-Off Systems offer simplicity and cost-effectiveness. Choosing the right machine helps you avoid spending on unnecessary features and ensures you invest in a system that fits your needs and offers great value.

Selecting the Right Wire Pay-Off Machine

Selecting the appropriate Wire Pay-Off Machine is a critical decision that requires careful consideration. Dynamic Wire Pay-Off Machines are recommended for large-scale production due to their precision in speed and tension controls, which facilitate uniform wire dispensing and enhance product quality. Additionally, they efficiently manage larger wire reels, thereby reducing labor requirements.

For smaller operations, Static Wire Pay-Off Systems may be more suitable. These systems are cost-effective while providing tailored solutions for your specific needs.

A comprehensive analysis of your operation is essential to identify the most suitable Wire Pay-Off Machine. Regardless of the system chosen, its importance in shaping your entire wire handling process cannot be overstated.

Maintenance and Safety Considerations

Proper maintenance is essential to ensure the optimal performance of your Wire Pay-Off Systems. Regular servicing and timely replacement of worn-out components will minimize downtime and enhance productivity. Additionally, adhering to the manufacturer-recommended operational guidelines is crucial for ensuring the safety of personnel and the integrity of the equipment.

Wire Pay-Off Machines are sophisticated machinery that require careful handling and maintenance. Neglecting their upkeep or improper use can compromise efficiency and safety. By maintaining a diligent approach to the care and operation of these machines, you can maximize their effectiveness and ensure a safe working environment.

Optimizing Production With Wire Pay-Off Machines

Selecting the appropriate Wire Pay-Off Machine for your production scale encompasses more than just size considerations. It involves evaluating the efficiency and consistency that the machine can bring to your operations. Whether you need a Dynamic Wire Pay-Off Machine for large-scale production or a Static Wire Pay-Off System for smaller operations, making an informed decision is crucial.