Advantages of Wire Flattening & Shaping Lines

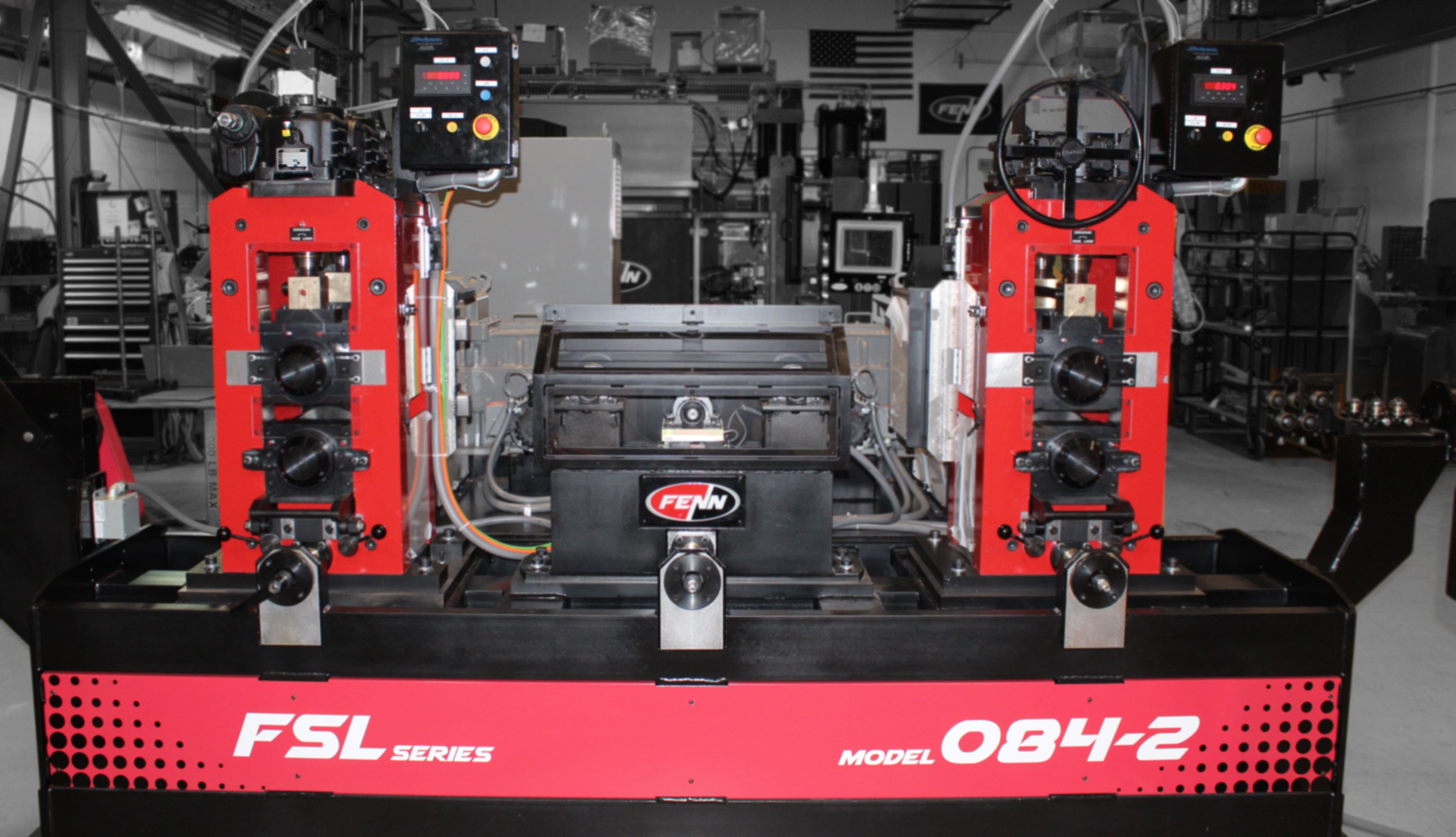

FENN Wire Flattening & Shaping Lines

Turks heads are often included as one component of a wire flattening and shaping line. Different functions of a turks head can include:

- Drawing rod or wire through rolls to form rectangular, diamond, or specialty shapes.

- Edging, embossing, or tempering flat strip.

- Sizing and edging rectangular wire.

Turks Heads, Rolling Mills, and More…

FENN wire flattening & shaping lines are high-speed, high production and accurate solutions to shaping and forming wire. A wire shaping line typically includes one or more pull-through or power-driven turks heads to produce the desired finish shape. Other components that may make up a wire flattening and shaping line can include rolling mills for initially breaking down the wire, edgers for controlling corner radii, and traversing take ups for collecting the finished product. Finished stock can be coiled at the end of the line or cut to desired lengths. Standard wire shaping lines including turks heads can accommodate speeds up 1,500 FPM. However, for specialty applications FENN has provided flattening lines with speeds up to 3,000 FPM.

Video of a FENN 3-Stand Wire Flattening Line

Turks Heads Types & Models

Turks heads that are used in mill configurations are plain, universal, and combination types. Plain models include 4 axes of adjustment, so each roll moves independently. Because rolls are set up directly in line with each other, plain models are best for producing special shapes. Universal models include 2 axes of adjustment for up & down, and in & out movements. Any square or rectangle within the capacity of the turks head can be set up by merely adjusting the position of the rolls; easiest for set up of standard width and thickness. A combination model turks head offers the most flexibility in setting up rolls and includes 6 axes of adjustment. A combination turks head can be used in either a U-type or P-type configuration.

Additionally, when integrated into a line, turks heads can either be pull-through or power-driven. Pull-through configurations require an external pulling device such as a capstan or shedding drum. Although capstans do take up more floor space, they are useful for products that require high amount of back tension. Power-driven units may be the best choice for customers processing precious metals because it eliminates the need for a capstan, which must be threaded; and the threaded material creates more scrap. Dependent upon the customer’s application and available floorspace, FENN will recommend a design that will best suit individual requirements.

Advantages of FENN Wire Flattening & Shaping Lines:

- Versatility: FENN can design and build wire shaping lines to accommodate many sizes and shapes for a wide variety of applications. FENN wire shaping lines can be used for applications from .002” to 2.75” (.05mm to 70mm) inlet diameter. Turks heads may be used in tandem with rolling mills, in either a 2HI or 4HI configuration, dependent upon production requirements – as part of a larger wire flattening & shaping line.

- Economical: Turks head and mill rolls wear slowly and can be adjusted to compensate for their wear. They can be reground several times, greatly increasing their life. For rolling mills, lateral adjustment axes are added allowing the roll face to be moved relative to the wire, which enables more of the roll face to be utilized prior to regrinding. For power-driven turks heads, designs have been updated which allows for removal of drive rolls without disconnecting drive shafts, which reduces downtime for more productivity. Lines can also be upgraded overtime to stay current with safety regulations and can be added to or modified if production processes change.

- Turks Head Accuracy: Accurate dimensions of thickness and width are imparted simultaneously, reducing the number of operations required, and eliminating inaccuracy in one plane sometimes caused by a subsequent operation in the other plane.

- Rolling Mill Accuracy: Mills maintain thickness accuracy; width is a natural spread to the sides and is not directly controlled by the mill. Width can be controlled using a turks head as a next step on the production process. Other devices such as edgers can also be used to control width during a rolling process.

- Increased Output: Fast operating speeds, large reel capacity, quick set-up, and sizing (vertical for mill and vertical & horizontal for turks heads) result in increased production quantities.

- Customized Software: FENN provides custom solutions to suit your needs. Some

examples include:

examples include:

- Individualized full visual breakdown of the line with status indicators and subsections for set-up

- Alarm diagnostics for operator use

- HMI programmable pass schedules

- SPC & data collection system

- Automatic speed & tension control

- Automatic gauge control for maintaining part accuracy, which minimizes scrap

Applications and Industries

Many applications can be achieved with a single stand or multi-stand arrangement (FENN has designed and built lines with anywhere from 2 to 8 stands). For certain applications with more aggressive reductions, additional stands may be added or used in conjunction with edgers, draw blocks, pay-offs & take-ups, turks heads, dancers, and rolling mills to process the material requirements. FENN has integrated wire flattening & shaping lines in tandem with commercial annealing equipment, allowing the customer to make their product in one efficient pass. FENN’s team of experienced engineers determines the correct arrangement or necessary equipment for each customer’s specific set of requirements.

While there are many different options in the industry, FENN has been trusted across the globe for over 120 years to provide quality and reliable wire flattening & shaping lines for the most demanding production requirements. FENN’s wire shaping lines are not limited to the rolling of natural edged flat wire. Square, rectangle, trapezoid, oval, half-round, and many other shapes can be rolled with the proper selection of equipment. Examples of some industries that use FENN wire flattening and shaping lines are solar, medical, orthodontic, automotive, industrial, as well as well-screen and retaining ring wire. With ample experience in the fields of engineering and manufacturing metal forming machines, FENN provides state-of-the-art equipment to suit your most demanding production requirements.