Torin Spring Coilers

Spring Coilers available for wire diameter ranging .003” – .750”

Spring Coilers Designed & Built In-House

Torin is proud to continue a “Made in America” legacy, with every spring coiler machine being designed and built in our East Berlin, Connecticut headquarters. FENN has been a leader in quality metal forming machinery for over 120 years.

Our experts take the time to design and build the right machine to fit your exact specifications and fulfill your unique production requirements. With experience building standard metal forming equipment, as well as customized metal forming machinery solutions – FENN’s product and service offerings can help increase precision & productivity for your business.

Coiling machines to keep your business competitive

Adaptability is the key to success in today’s competitive manufacturing market. To help your business stay competitive, FENN is pleased to offer the Torin line of high speed, versatile spring coiler machines, now available in both single or dual point configurations. Choose the spring making machine that best fits your business needs.

A long history of experience

For decades, Torin has long been recognized as the premiere spring coiler brand. In 2003, FENN acquired the brand from BHS-Torin, and continues the legacy of producing high-quality machinery made in the USA. Now under the leadership of BHS Torin veteran Ryan Cutter, FENN continues to invest in developing the highest quality spring making machines available on the market.

Single Point Spring Coiling

FZ Series Torin Single Point Spring Making Machine

FENN offers single point Torin coilers available for wire ranging from .003” to .750” in diameter. A Torin FZ Series spring coiler can produce a variety of springs including, but not limited to, compression, extension, torsion, belting, magazine, constant force, shaped wire, wire forms, and rings.

Torin Single Point Spring Coilers Available in Four, Five, or Six Axis!

Every Torin spring coiler comes standard with 4 axes, which fulfill the feed, diameter, pitch, and cut functions. For customers who require greater versatility, the torsion and lateral coiling point functions of axes can be added. These additional axes enable the production of springs such as torsion, wire forms and hooked extension springs.

| Machine Size |

00 FZ-100 |

0

FZ-10 |

0-1/2

FZ-810 |

1

FZ-11 |

1-1/2

FZ-115 |

2

FZ-12 |

2-1/2

FZ-125 |

3

FZ-23 |

4

FZ-24 |

5 FZ-25 |

|---|---|---|---|---|---|---|---|---|---|---|

| Wire Diameter (In) |

.003 – .015 | .008 – .028 | .010 – .040 | .015 – .080 | .032 – .135 | .047 – .177 | .080 – .275 | .125 – .375 | .160 – .625 | .250 – .750 |

| Wire Diameter (mm) |

.076 – .380 | .200 – .700 | .250 – 1.00 | .400 – 2.00 | .800 – 3.50 | 1.20 – 4.50 | 2.00 – 7.00 | 3.20 – 9.50 | 4.00 – 16.0 | 6.30 – 19.0 |

| Wire Diameter Torsion (in) |

.003 – .015 | .008 – .028 | .010 – .040 | .015 – .080 | .032 – .135 | .047 – .177 | .080 – .250 | .125 – 3.25 | .160 – .440 | .250 – .500 |

| Wire Diameter Torsion (mm) |

0.08 – .380 | .200 – .700 | .250 – 1.00 | .400 – 2.00 | .800 – 3.50 | 1.20 – 4.50 | 2.00 – 6.40 | 3.20 – 8.30 | 4.00 – 11.2 | 6.30 – 12.7 |

| Minimum Index | 3 | 3 | 4 | 3 | 3 | 3 | 3 | 3 | 5 | 5 |

| Spring Body Max (in) |

.281 | .875 | .875 | 1.75 | 2.25 | 3.25 | 4.25 | 5 | 6 | 10 |

| Spring Body Max (mm) |

7.1 | 22 | 22 | 44 | 57 | 83 | 108 | 127 | 152 | 254 |

| Feed Length | UNLIMITED |

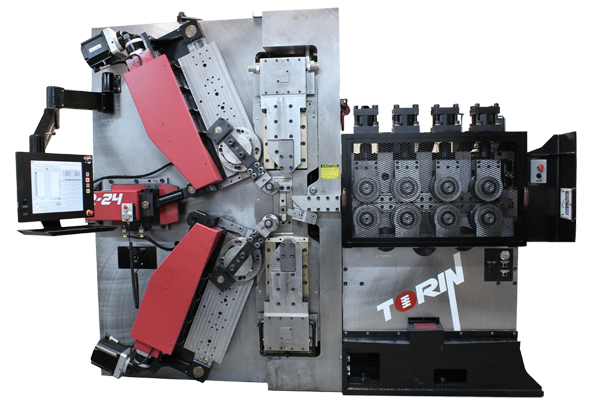

Dual Point Spring Coiling

R-Series Torin Dual Point Spring Making Machine

The Revolution Series utilizes the same robust mechanics, and reliable, accurate controls as the FZ Series with the use of two point coiling technology. FENN offers dual point Torin coilers available for wire ranging from .008” to .750” in diameter. Torin’s R-Series of dual point spring coiling machines can manufacture round compression and extension springs. Torin spring coilers are designed & built for fast set-up and changeover of springs with the user-friendly spring program generator. Learn the differences between Dual Point Spring Coilers vs. Single here to learn more about how FENN can develop a solution to meet your requirements.

| Machine Size |

0 R-10 |

1

R-11 |

1-1/2

R-115 |

2

R-12 |

2-1/2

R-125 |

3

R-23 |

4 R-24 |

5 R-25 |

|---|---|---|---|---|---|---|---|---|

| Wire Diameter (In) |

.008 – .028 | .015 – .080 | .032 – .135 | .047 – .177 | .080 – .275 | .125 – .375 | .250 – .625 | .375 – .750 |

| Wire Diameter (mm) |

.200 – .700 | .400 – 2.00 | .800 – 3.50 | 1.20 – 4.50 | 2.00 – 7.00 | 3.20 – 9.50 | 6.35 – 16.0 | 9.50 – 19.0 |

| Minimum Index | 3 | 3 | 3 | 3 | 3 | 3 | 5 | 5 |

| Spring Body Max (in) |

.875 | 1.75 | 2.25 | 3.25 | 4.25 | 5 | 6 | 10 |

| Spring Body Max (mm) |

22 | 44 | 57 | 83 | 108 | 127 | 152 | 254 |

| Feed Length | UNLIMITED |

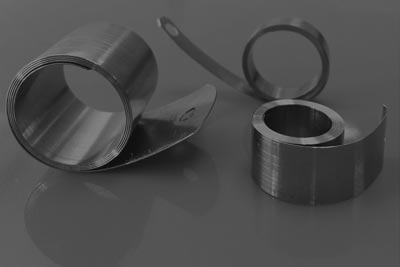

Constant Force

Since the 1950s, Torin has been supplying constant force coilers – a specially designed coiler for manufacturing constant force springs. FENN has developed the CF-Series of coilers into reliable machines capable of making top-quality constant force springs. As part of FENN’s unique design, the same set of feed rolls can be used for the entire range of the machine – there is no need to change rolls for varying thickness of material. FENN offers the complete package for your constant force coiling operation – machine, press & guiding, exit chutes, payoffs & ovens. Contact us to learn more!

Benefits of Torin’s Design

- Ensured parallelism of the feed rolls to maintain material alignment during production

- The same set of feed rolls can be used for the entire range of the machine

- Press can be designed to accommodate customer die sets

- FENN’s CNC machine allows for customized I.O. to control additional aspects of production

- Left & right-hand feeding capabilities

Possible Material Ranges & Models

- Although material outside these ranges can be accommodated, an example of the smaller material capabilities can range from .004” thick by .250” wide and an example of larger material capabilities can range from .040” thick by 2.00” wide (*Note: Required model size is dependent upon additional factors)

- For these ranges, FENN’s models include the CF-11, CF-115 & CF-12

- We can design additional model sizes for your requirements!

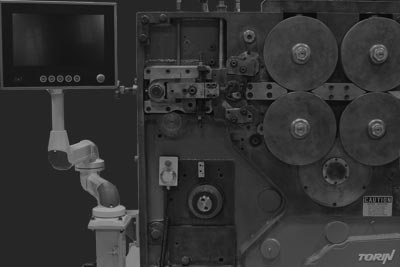

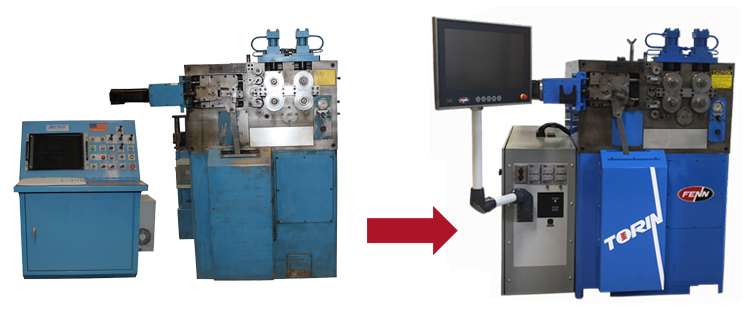

Retrofit & Upgrades

Retrofit Program for W Series Mechanical Coilers

FENN’s Electrical Retrofit program provides unmatched value: our highly knowledgeable, experienced engineers and factory technicians enable us to deliver retrofitted equipment at a fraction of the cost of a new machine. Let us help you maximize the potential and output of your Torin Spring Coiler with our CNC technology, all backed by our 1 year retrofit warranty! See our Mechanical Retrofit Brochure.

Control Upgrades are also available for older Torin servo controlled spring coilers. Give your spring coiler forming machine a complete control upgrade including software with the latest FZ Series features. With this package, eliminate the risk of relying on obsolete components. For more information, please see our Z Series and CNC Upgrades Brochure

Z SERIES & CNC CONTROL UPGRADES

Control Upgrades are also available for older Torin servo controlled spring coilers. Give your spring coiler forming machine a complete control upgrade including software with the latest FZ Series features. With this package, eliminate the risk of relying on obsolete components. For more information, please see our Z Series and CNC Upgrades Brochure.

ELECTRICAL RETROFIT PROGRAM FOR MECHANICAL SPRING COILERS

Now you can benefit from maximized potential and output with our CNC technology for a fraction of the cost of a new machine. By retrofitting your mechanical Spring Coiler, you can increase your machine’s capabilities with high quality OEM parts to keep your machine running at optimum performance. Trust our experts to provide a robust solution built to last as long as our machines do! Learn more about the benefits of an electrical retrofit for your Torin machine.

Preventative Maintenance Programs

Don’t risk downtime!

The best service FENN can provide is preventing the need for unscheduled service.

Allow the experts at FENN to keep your machine running at the highest level of productivity.

Our program includes:

- An annual plant visit which consists of a 50-point inspection by an OEM certified technician, to evaluate crucial mechanical and electronic components of your machine to prevent issues before they effect your production

- Included is a detailed inspection report, providing valuable information on the condition of your machine, areas of concern and recommended repairs

- One additional complementary plant visit – decide when and how to use the visit to fit your business needs.

- Training: Ensuring your staff is adequately trained to use the metal forming machine to its full potential

- Service: Installation of parts resulting from your initial inspection

- Repair: Resolve any additional service or maintenance issues that arise throughout the year

- Program participants receive an exclusive 15% discount on all our quality OEM spare parts

- Enjoy Premium Accessibility! Outside of scheduled PM visits, PM customers will receive preferential treatment in the service que.

- Software updates for FZ and R-series spring coilers are included in the program!

Spares from the OEM!

FENN understands that uptime is key to your business’ productivity and profitability. We offer a full range of spare parts available for both FENN and Torin metal forming machines. With an extensive inventory, FENN can offer a wide array of parts shipped quickly to your door. Our knowledgeable staff will help to ensure you receive the necessary parts to keep your equipment running effectively with minimal downtime. Using FENN spare parts is an essential aspect to maximizing your machine’s efficiency. Don’t know exactly what you need? Our experienced staff will take the time to work with you to understand your unique requirements.

Upgrade Program for Your Aging Machinery

Because FENN machinery upholds a legacy of being quality, reliable and long-lasting, FENN has developed an upgrade program for upgrading, rebuilding or retrofitting your existing FENN equipment. Customers can maximize their machine productivity for aging equipment and extend the machine’s usable life.

We’re Here For You – Training, Support & Service

As a century old company, we are proud of the equipment we design and build, always ensuring it meets your production requirements. We offer comprehensive training programs that can be tailored to meet your business’ needs. Whether you have purchased a new metal forming machine, upgraded existing equipment or your experienced staff is retiring, FENN is available to answer questions and offer training to keep your business productive. Let us know how we can help!